No products in the basket.

Dereks Tech Tips – Issue 6

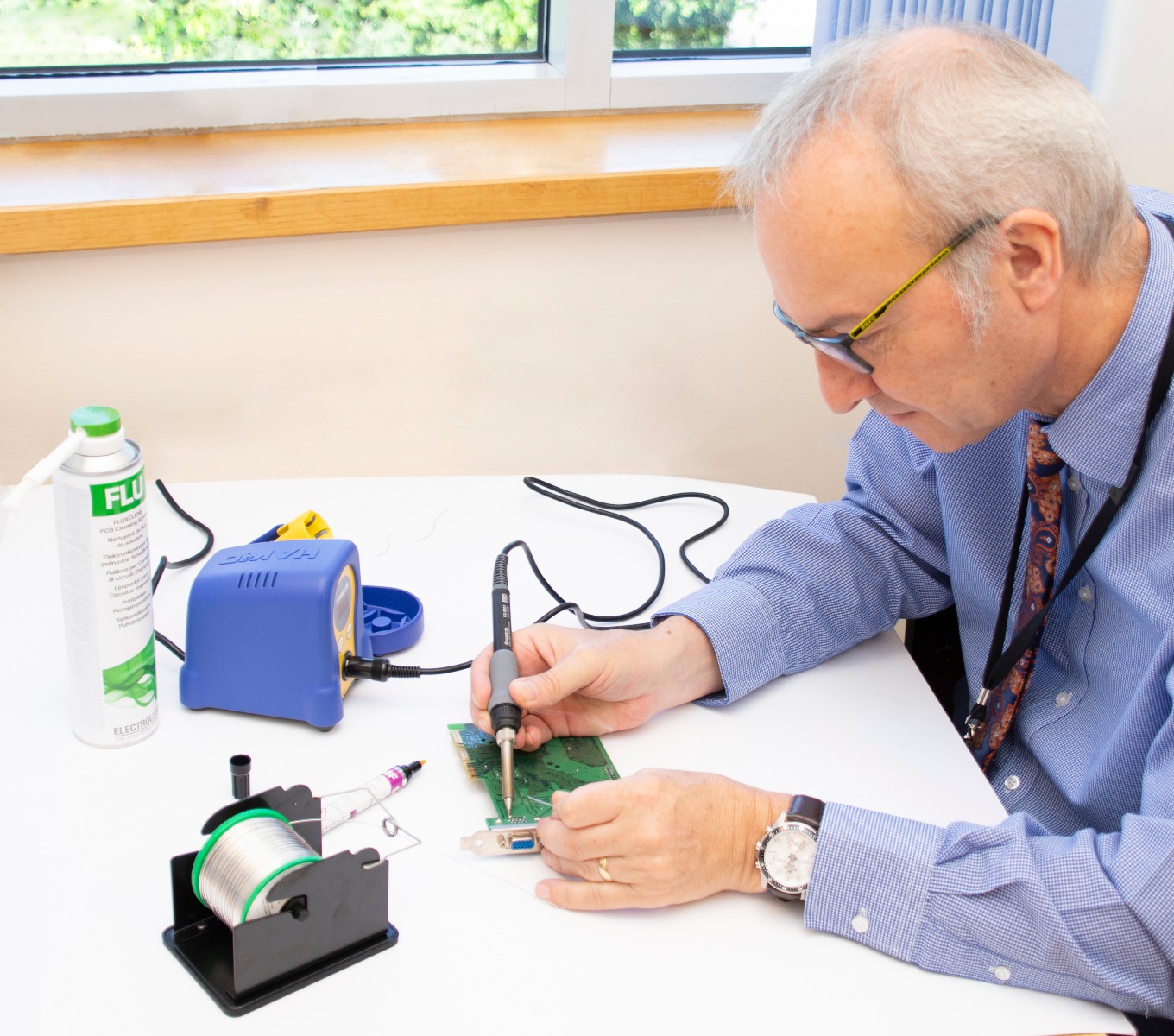

Maintenance & Inspection Tips to Maximise Your HAKKO Equipment

In this edition of Hakko Tech Tips, we will explore some simple maintenance and inspection routines to help you achieve maximum output from your Hakko tips and equipment. By implementing routine daily or weekly practices, you can genuinely increase the performance of your soldering process.

Is there a standard maintenance/inspection system that I should follow for my Hakko soldering station?

For station-type soldering irons, which have become mainstream products in recent years, it is recommended that customers perform regular maintenance and inspection checks, which include leak voltage, tip-to-ground resistance and tip temperature.

To prevent device damage and soldering failure, it is advisable to periodically perform inspections weekly, or even daily. We recommend using the Hakko FG-101B Soldering Iron Tester, which is our newest model and is capable of measuring leak voltage, tip-to-ground resistance and tip temperature. It provides fast and accurate measurements, error-free operation and comes equipped with the new AS5000 long life sensor which lasts up to 30 times longer than a conventional sensor.

Let’s explore these 3 inspection checks further. Firstly, leak voltage should be checked periodically because if an electric current is leaked from the solder tip this could have an adverse effect on the PCB/components being soldered. Even though an insulating ceramic material is used, long-term use can cause the heating element to deteriorate and the leak voltage to increase. Also, an accumulation of oxides on parts such as the tip/element cover, can cause contact failure and leak voltage to increase. The lower the leak voltage, the better. All Hakko soldering iron stations have been designed with the leak voltage set to less than 2mV. If the leak voltage is higher the heating element has deteriorated in some way. Visual inspection is likely to reveal that the element has oxidized/blackened. If this is the case replace the heating element. If oxides have accumulated on other parts, simply remove the oxides with steel wool or a fine-grade abrasive cloth.

The second inspection to incorporate into your routine is for tip-to-ground resistance. Oxide and flux that has adhered or burnt on to the tip, element cover and nut will cause an increase in the tip-to-ground resistance. Consequently, the leak voltage will become higher, which ultimately impacts on soldering performance. As with leak voltage, the lower the tip-to-ground resistance, the better. Therefore, all Hakko soldering iron stations have been designed with the resistance set to 2Ω or less. If your tip-to-ground resistance measurement is higher, polish the contact sections such as the tip and element cover with a fine grade abrasive cloth or steel wool to remove any oxide films.

The third inspection involves checking the tip temperature. If the heating element is oxidized, thermal conduction will deteriorate and the tip temperature will reduce, possibly resulting in the production of a poor quality solder joint. To prevent poor soldering, we recommend measuring the tip temperature daily with either the FG100B or FG-101B tester.

Why would the tip of my soldering station not heat up correctly? What could be potentially causing this?

There are a number of simple factors that could be causing the tip to not heat up correctly. To trouble shoot this particular issue on an FX951 station, please conduct the following checks:

- Check if the unit is in sleep mode. If so, press buttons on the front panel to release initial sleep mode. If heat is still not being produced, then switch off and switch back on again (Auto power shut off). If there is a potential Sensor Error, shown as “S-E” on the display the most likely cause is incorrect insertion of the soldering tip into the soldering iron handle. Tip failure could also be the root cause so measure the resistance value in the soldering tip heater The normal resistance value should be 7.2 Ω to 8.8 Ω at ambient temperatures (15 to 25°C). When the resistance value is not normal, replace the defective soldering tip with a new one. Further advice regarding the resistance checks can be found in your Hakko FX951 Instruction Manual. If there is a potential Connector Error, Shown as “C-E” on the display, a soldering iron other than Hakko FM-2026, FM2028 or FM2032 is being used or the connector plug may not be fully inserted. Check that the soldering iron is properly connected to the soldering station.

- If nothing is shown on the display, this is likely to be from a total power failure. This could be caused by a power cable that is not fully seated or a blown fuse in the power receptacle. Check the connection of the power cable and condition of the fuse. If nothing still appears on the display then it is likely that a PCB or transformer may be faulty. Contact a Hakko office, service centre or distribution outlet near you for further assistance.

- Finally, your station may be faulty if the symbol “—“ is shown on the display. In this incidence, please return the station to your supplier.

What is the usual ‘tip life’ that I could expect with my Hakko equipment?

This is a bit like asking how long a piece of string is! Tip life will be dependent on the type of solder/flux being used, as well as the set temperature and type of soldering being carried out. Hakko Soldering iron tips are designed with a Copper core for good thermal conductivity and plated with Iron for less corrosion.

The soldering part of the tip is then plated with Tin and a further area is plated with Chrome in order to prevent the expansion of the tinning area up the tip. Hakko tips are widely renowned for their durability and performance, so with some daily maintenance, you can help to maintain and extend the lifetime of your Hakko tips.

Are there any daily maintenance routines that I should follow to ensure that my Hakko equipment is always performing at its’ best?

Performing a regular maintenance regime in a clean, dry and well ventilated area will help to ensure that your Hakko equipment stays in good condition. We have looked at maintenance practices for soldering stations, such as periodic checks of leak voltage, tip-to-ground resistance and tip temperature but if you want to fully optimise the performance of your equipment, there are further checks that you can do.

- Firstly, always reduce solder tip oxidation by keeping the pre-set temperature as low as possible to enable sufficient melting of the solder whilst still producing a satisfactory soldered joint.

- Try to avoid increasing the tip temperature to more than is actually needed. When changing the solder tips, always turn off the power for safety reasons and to prevent internal arcing which can reduce both tip and soldering iron handle lifespan. It is also worthwhile switching off the power between applications to reduce the rate of oxidation.

- It’s a great habit to cover the tip with solder before placing the soldering iron into its holder during soldering work and at the end of a shift.

- Check that the filters are changed regularly in your de-soldering unit to help extend the equipment life and keep soldering tips/nozzles clean with the Hakko range of cleaning aids.

Is there a correct method that I should always follow for tip replacement?

Hakko’s soldering systems have been designed to provide ease of use for operators, therefore, tip removal is very straightforward. In soldering systems such as Hakko’s FX951, FM2028 or similar, simply hold down the lock release buttons on the sleeve assembly whilst pulling out the sleeve/tip from the handle. Then, hold the front of the sleeve and push the tip out (back to front). Tip insertion will be the same but in reverse order. In Hakko’s FX888D and similar stations turn the nut counter-clockwise and carefully remove the tip enclosure and tip from the heating element. Re-fitting of the tip is exactly the same but again, this will be in reverse order, and do bear in mind that it isn’t necessary to overtighten the nut upon re-fitting.

We welcome feedback from our customers and potential new customers, so please do talk to one of our team if you have any questions. Look out for next month’s Hakko Tech Tips where we will be providing more advice on how to get the best performance from your Hakko equipment.

For further information about Hakko, please visit www.hakko.co.uk.