No products in the basket.

How to use the temperature probe for hot air rework system (No. C1541)

Let’s look at the adjustment method using the analog Hot Air model HAKKO FR-801 as an example.

Step 1) Use Sensor B to determine HAKKO FR-801 setting conditions required for rework.

* For how to use Sensor B, see the following pages.

Step 2) First, select one unit to be “Unit A” for use as a reference.

Attach the nozzle to Unit A and mount Sensor A at the specified position.

* For how to use Sensor A, see the following pages.

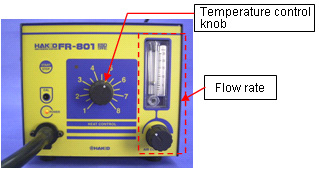

Step 3) Measure the temperature of hot air blown from the nozzle and record the conditions of [unit A] such as “temperature” “Blow rate” “Position of knob” etc.

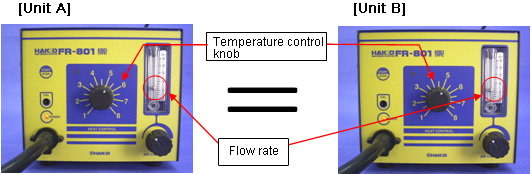

Step 4) Attach the similar-shaped nozzle to [unit B] and set the conditions of [unit A] which were recorded in step 2.

Step 5) Mount Sensor A to [unit B] and measure the temperature.

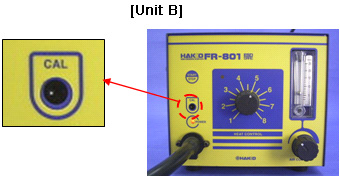

Step 6) Perform CAL adjustment so that the temperature becomes the same temperature as for [unit A] measured in the step 2.

* For digital Hot Air models such as HAKKO FR-802, HAKKO FR-803B, etc., adjust the temperature based on the offset values.