No products in the basket.

Point 1. Solder corrodes the iron-plated part and makes a hole.

| Tip life TOP | |

| POINT 1 | Solder corrodes the iron-plated part and makes a hole. |

| POINT 2 | The solder-plated part is oxidized in black and the tip is no longer wet with solder. |

| POINT 3 | The surface of the heating element insertion part oxidizes and the heat conduction becomes poor. (*Except for tips in composite type which has different structure) |

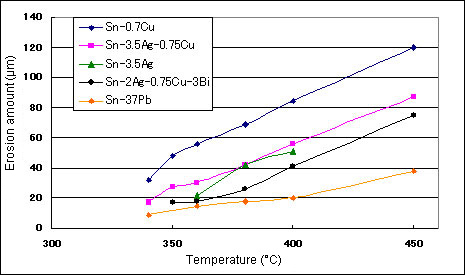

Solder can corrode the iron plating when the iron (Fe) forms an alloy with the tin (Sn) from the solder itself and melts into the solder. This phenomenon is common when using lead-free solder or setting at higher tip temperatures, and becomes especially marked at temperatures exceeded 400ºC. Figure 1 shows the test result of the erosion amount at tip temperature.

Fig. 1 – Erosion amount depending on solder and tip temperature ( φ1mm×5mm, 2000 times ) *If a tip gets a hole, it should be replaced with a new tip.