No products in the basket.

375, Accessories, HAKKO, Product catalogue, Shop by brand, Solder feeds, Solder wire / flux, Soldering equipment

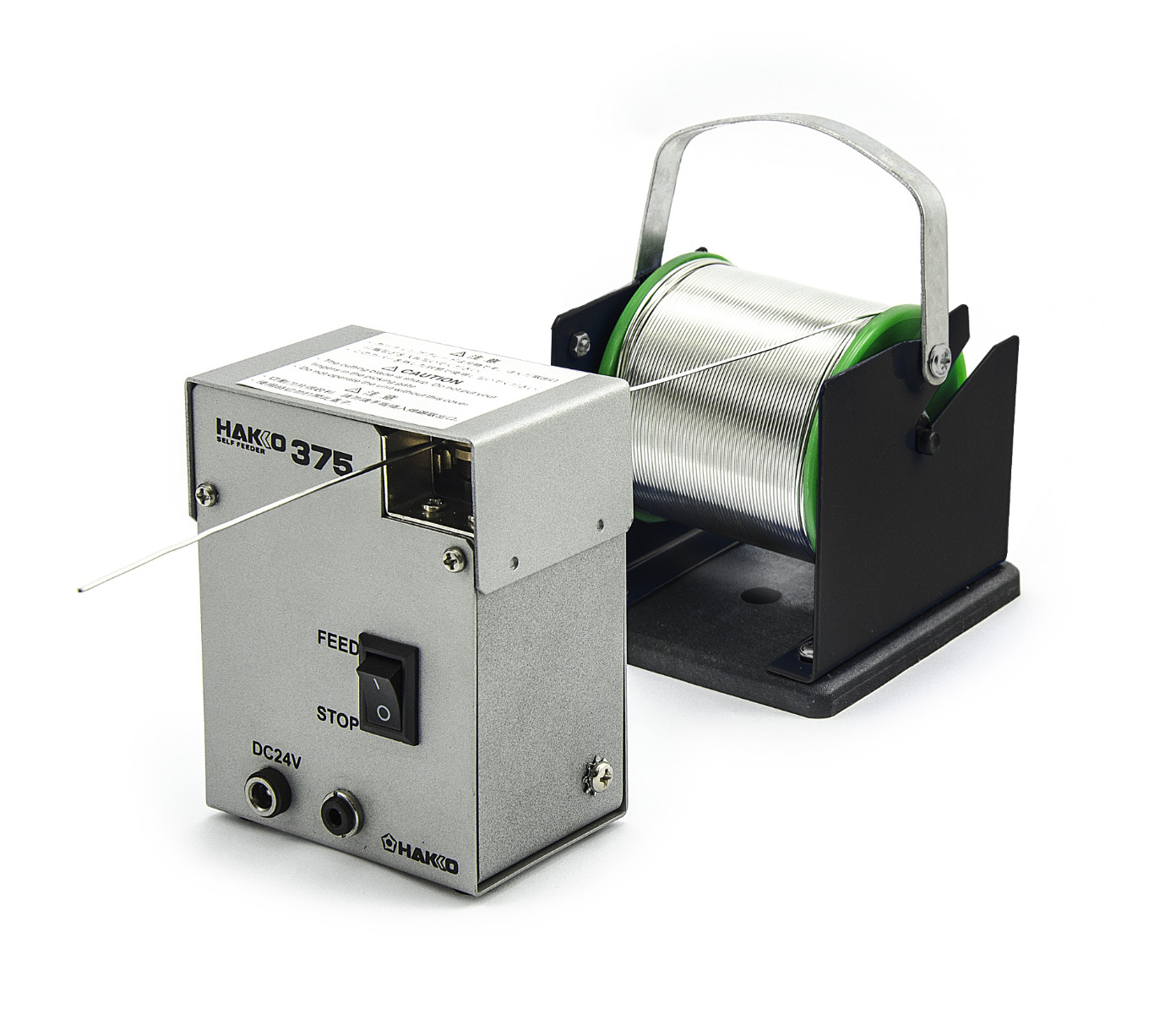

375 Compact Solder Feeder for 1.0mm Solder

SKU: H375-08

Availability:

Available for order*

375 Compact Solder Feeder for 1.0mm Solder

Puts a V-groove on the solder surface to reduce splash of solder and flux

Simple Controls on/off

£319.49 Excl. VAT

Available for order*

375-08 Compact Solder Feeder for 1.0mm Solder, smoothly feeds solder from the reel to your work to improve efficiency.

| Optimal for minimizing solder and flux splash Solder feeding equipment with V-grooving function for superior cost performance | |

| Minimize solder and flux splash As shown below, when solder is cut with a V-groove it enables the release of gas pressure generated by the flux, thereby suppressing splash. However, because the V-groove exposes the flux to outside air the solder cannot be stored for a long period of time. When using solder with the HAKKO 375, you can groove the solder that you require.

You can browse and download “Instruction Manuals” and “SDS” freely. | |

| Advantages of V-grooved solder |

| -Examination of solder/flux splash |

|

Test criteria

*The effect of solder and flux splashing prevention may differ under different operation conditions. | ||||||||

| -Measurement graph of flux splash amount |

|

|

| Applicable solder dia. ø0.3, ø0.5, ø0.6, ø0.8, ø1.0mm |

| Compact design |

Usage / Applications

| Can be applicable with the conventional solder reel stand. (Can be applicable with the HAKKO 611) -Application Examples |

|

| Use an option switch to increase efficiency Control the amount of solder that is fed using the ON/OFF switch. Use an option switch or hand switch to increase functionality even more. |

|

Also Available for the following Solder Sizes:

375-08 Compact Solder Feeder for 1.0mm Solder

375-07 Compact Solder Feeder for 0.8mm Solder

375-06 Compact Solder Feeder for 0.6mm Solder

375-05 Compact Solder Feeder for 0.5mm Solder

| Weight | 0.843 kg |

|---|