No products in the basket.

HAKKO, Product catalogue, Shop by brand, Soldering equipment, Soldering stations

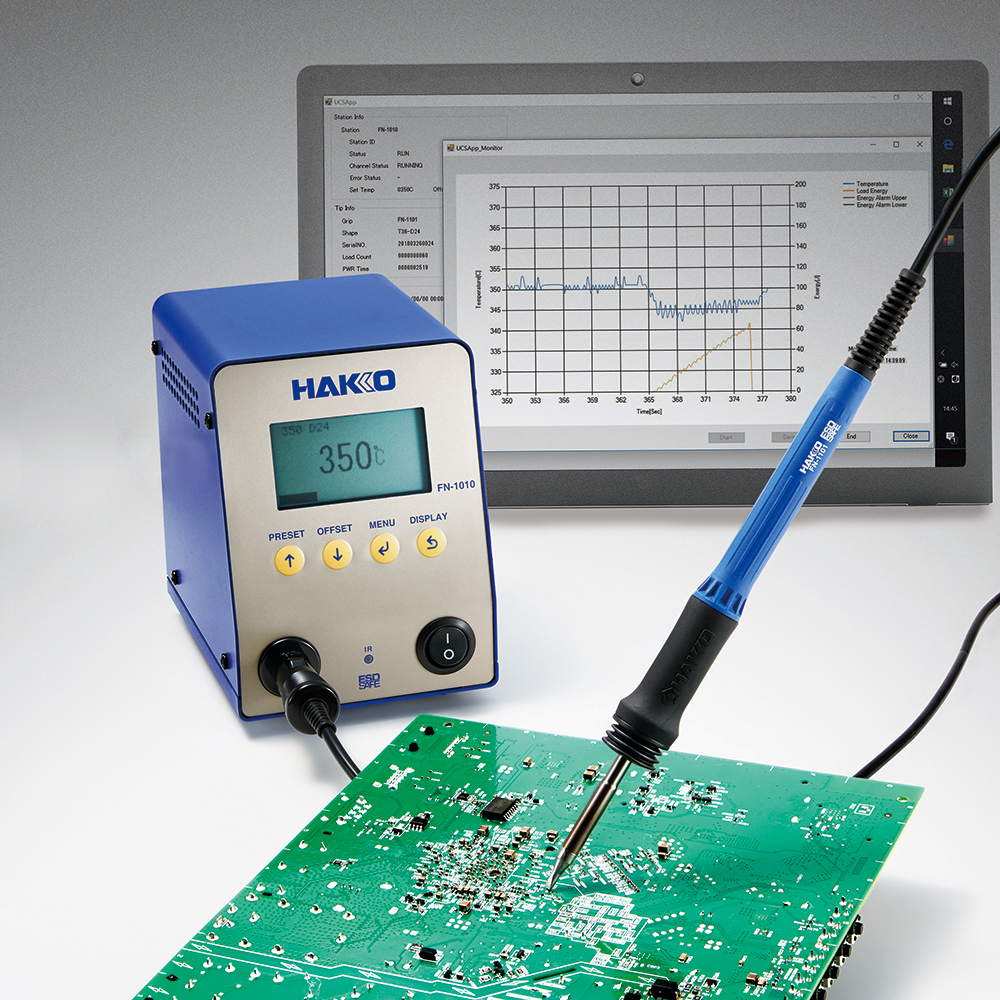

FN-1010 IOT Soldering Station

SKU: HFN1010-22

Availability:

In stock

Improve traceability

Minimize human error

Optimize soldering conditions

Ideal for use with support equipment eg. FG-100B

£1,275.22 Excl. VAT

In stock

Features of the FN1010-22 IOT Soldering Station

Enables human error-free temperature control and traceability of manual soldering process

FN1010-22 IOT Soldering Station and FG100B equipped with communication function.

Pioneer the future of soldering with advanced IoT technology

“Process control” and “Traceability” can be established through daily manual soldering operation.

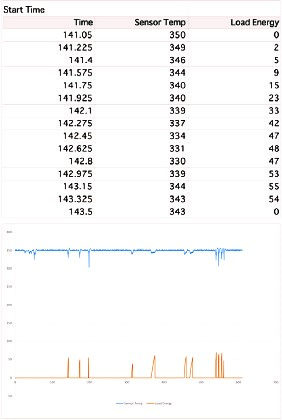

| Optimization of soldering conditions is now possible based on a variety of information in daily soldering process collected by FN-1010. Information to be collected

|  |

Automatic calibration/off-set can be completed once measurement result is sent through infrared.

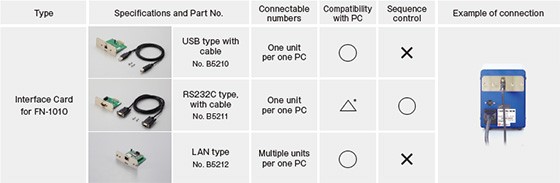

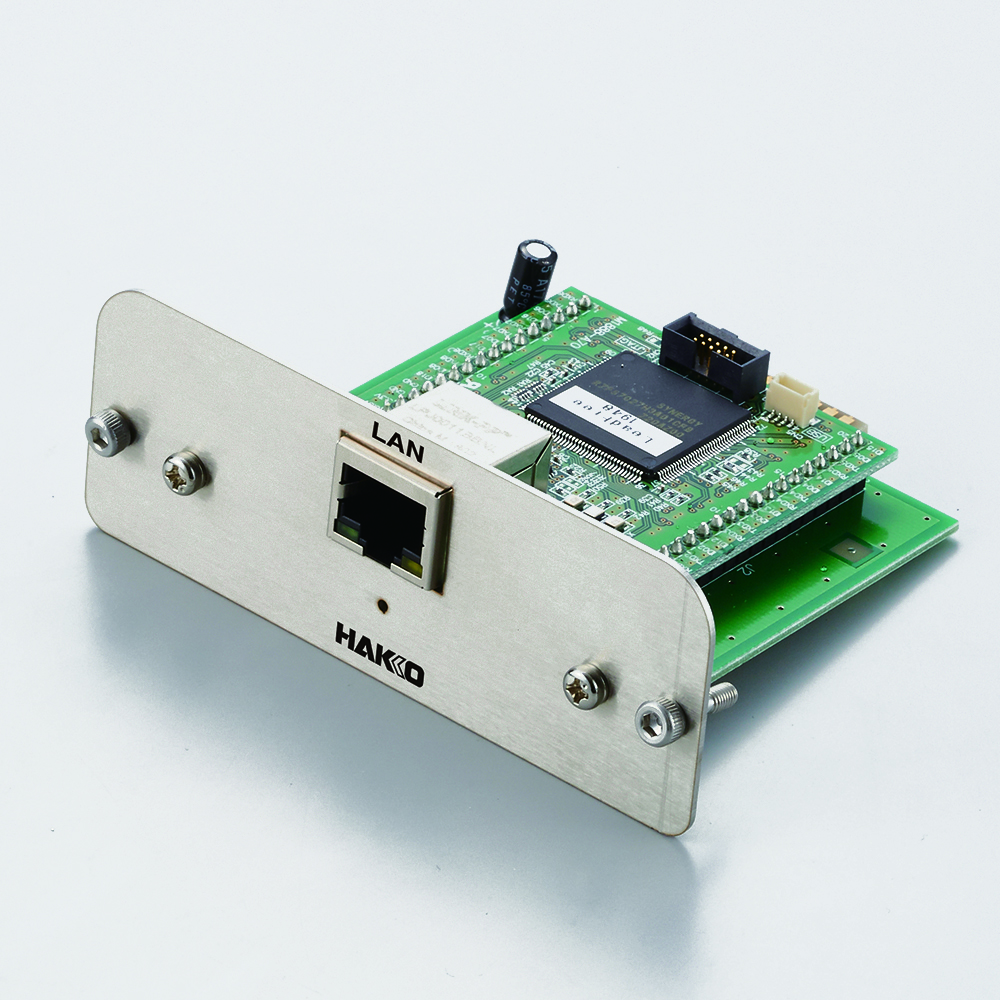

| Human error-free “tip temperature calibration ” and “off-set” can be established through daily manual soldering process. Results of measurement/calibration/off-set can be recorded automatically.Options for IoT communication Please choose the options according to the numbers of units and the connection port of PC and server. |  |

* RS232C cannot be connected with some PCs. Please check.

Visualize energy supplied during soldering

| It is now possible to visualize invisible energy supplied from T36 series Soldering Iron tip during soldering. And that makes it possible to control factors of soldering, which were impossible before.

|  |

HAKKO FN1010-22 IOT Soldering Station

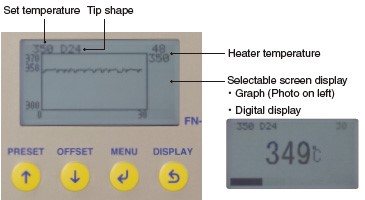

Real-time work status on the LCD screen

Improved button operation

Quick access to “Preset temperatures” and “Off-set mode” with one push.

It takes few button operation to access to most frequently used functions.

| Notification of alarm with sound and vibration Alarm can be notified with vibration in a noisy environment. |  |

| Free fall detection function Built-in motion sensor detects free fall and cuts the power. |

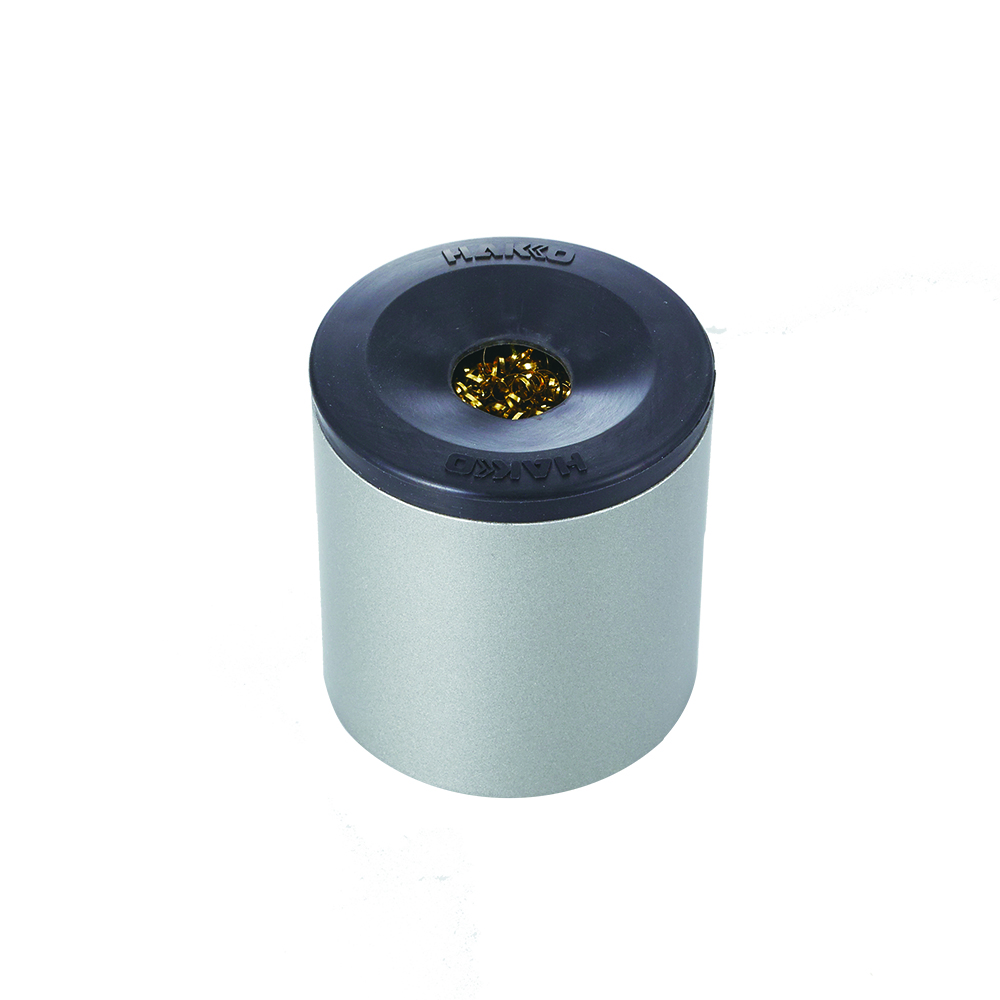

Tip cleaner with solder ball preventive design

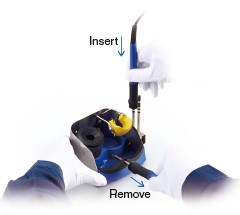

| Solder ball during tip cleaning can be reduced by 99% with devised cleaner designs such as smaller aperture, and set angle as well as position. * In-house comparison Tip replacement without heat resistant pad

|  |

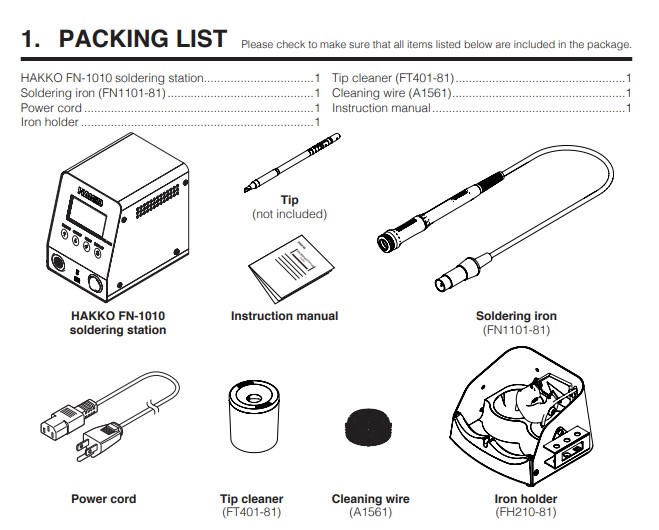

- FN1010 Soldering Station

- Power Cord

- Instruction Manual

- Soldering Iron (FN1101-81)

- Tip Cleaner (FT401-81)

- Cleaning Wire (A1561)

- Iron Holder (FH210-81)

Specifications

| Model No. | FN-1010 |

|---|---|

| Power consumption | 100W |

| Temperature range | 50 to 450ºC |

| Temperature stability | ±3ºC |

Station

| Output voltage | AC 21V |

|---|---|

| Dimensions | 104(W)×138(H)×152(D)mm |

| Weight | 1.9kg |

Soldering Iron

| Power consumption | 95W (21V) |

|---|---|

| Tip to ground resistance | <2Ω |

| Tip to ground potential | <2mV |

| Heating element | Composite heater |

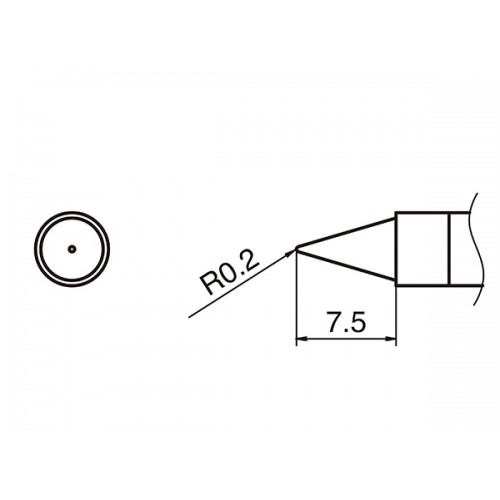

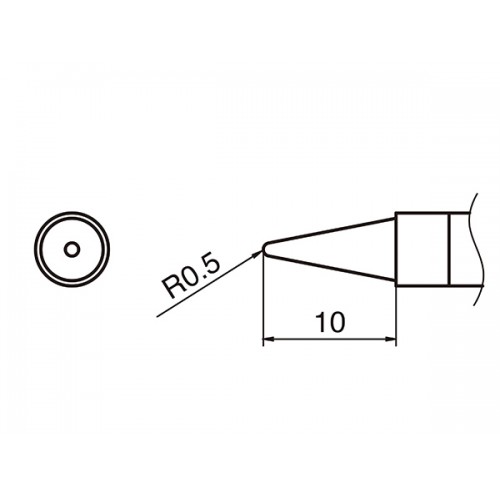

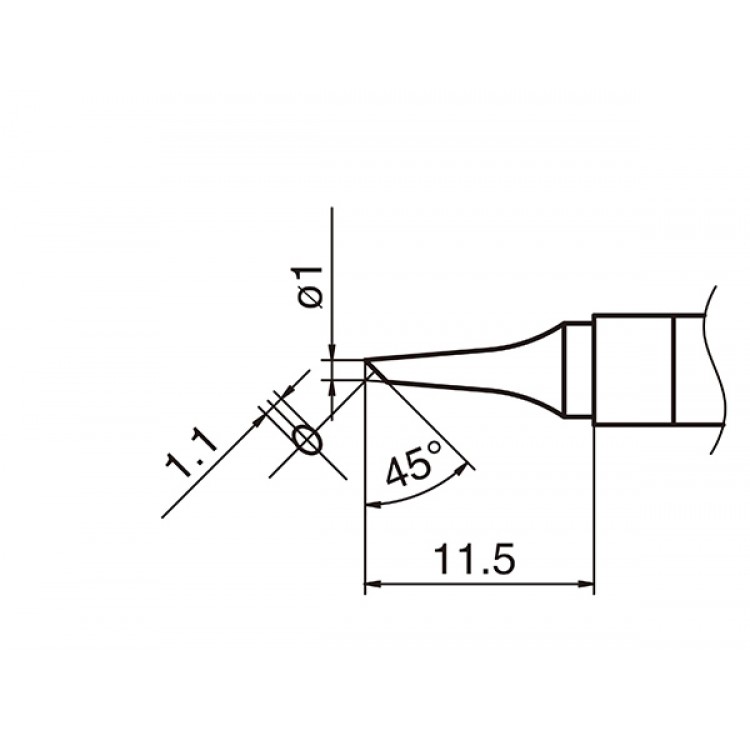

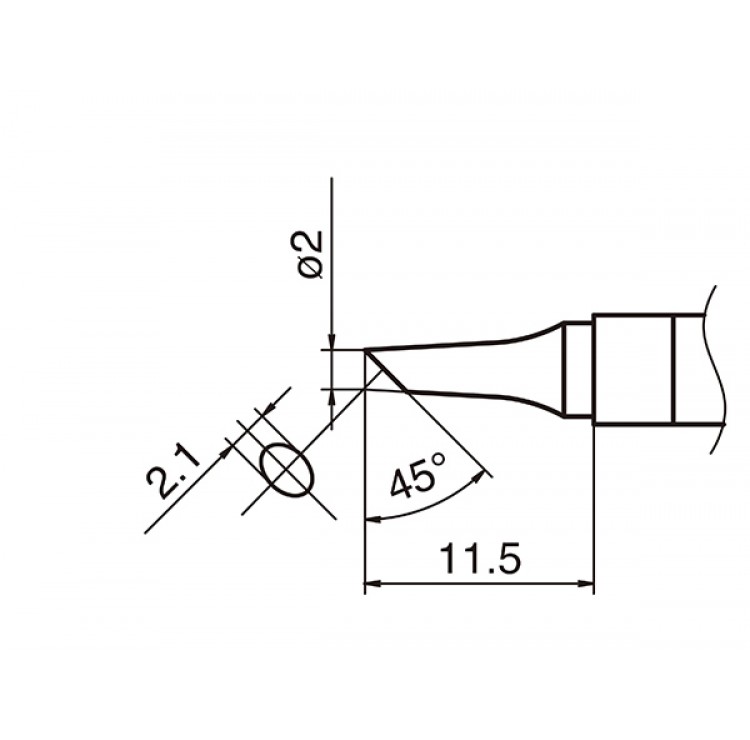

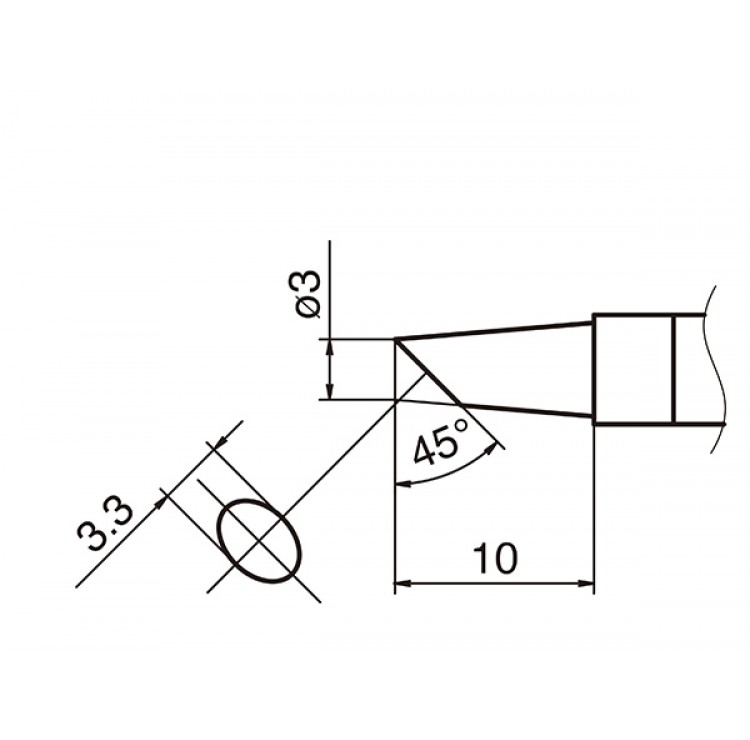

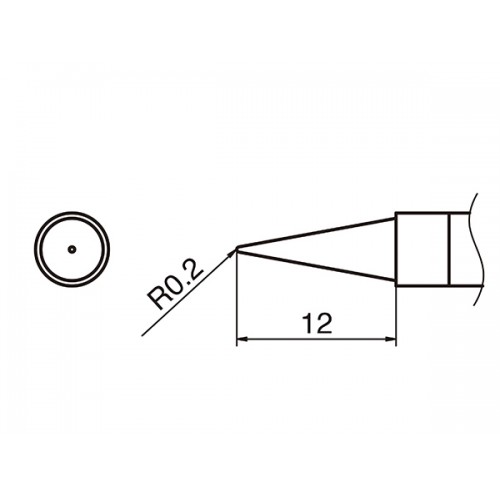

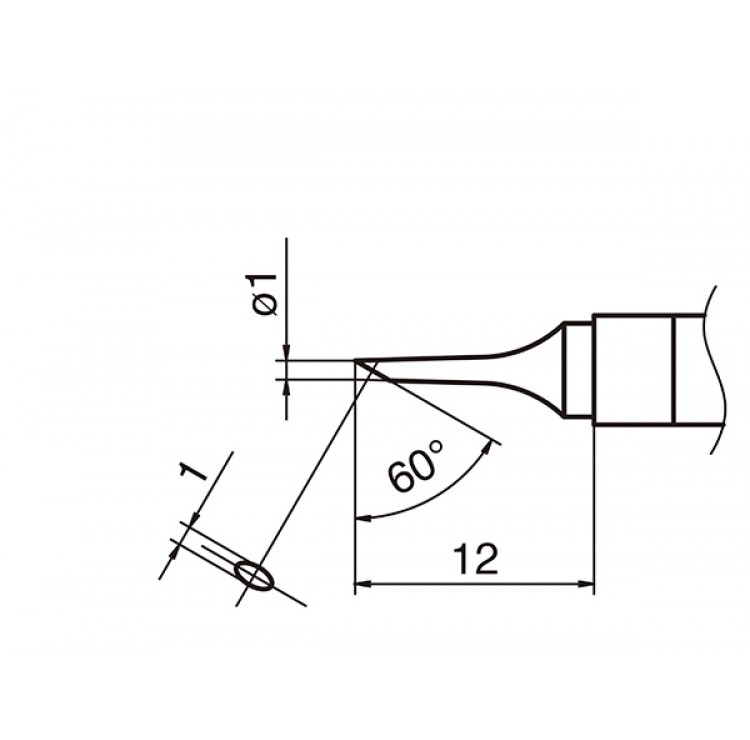

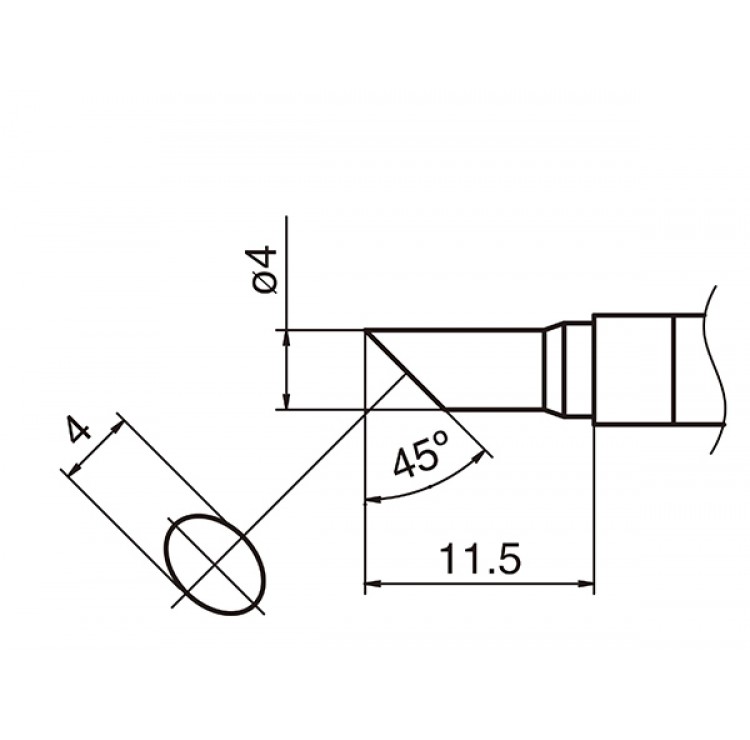

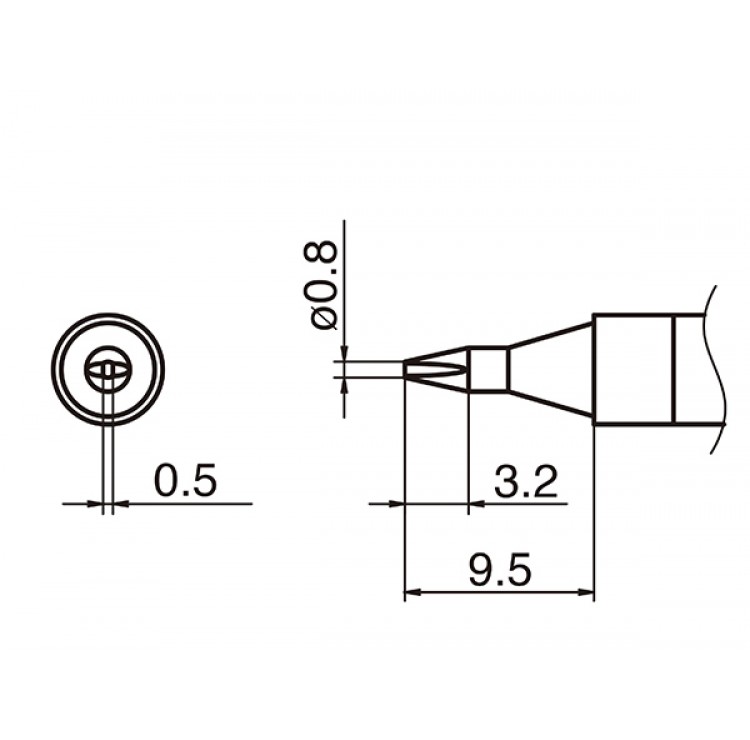

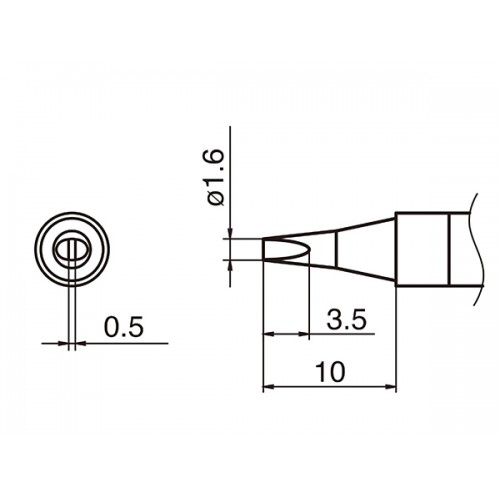

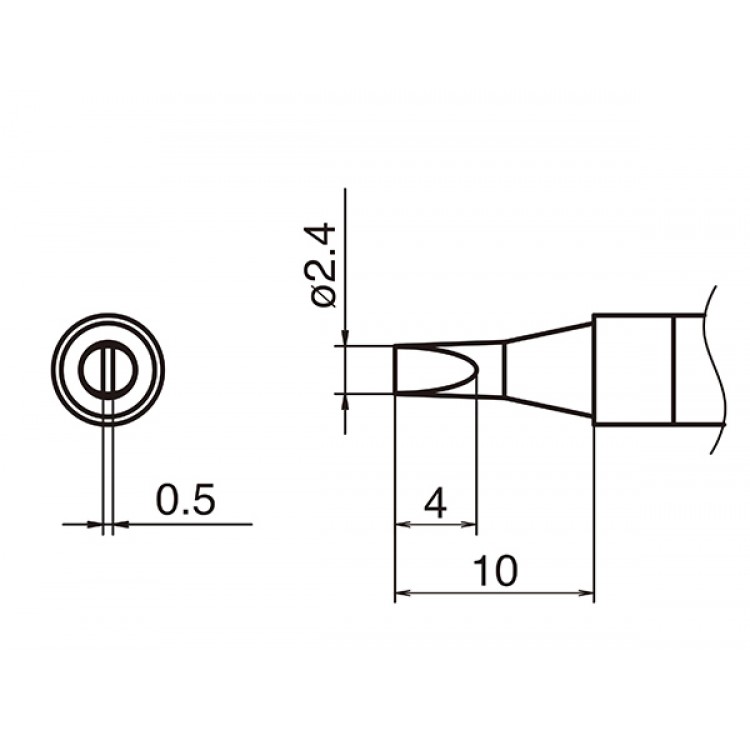

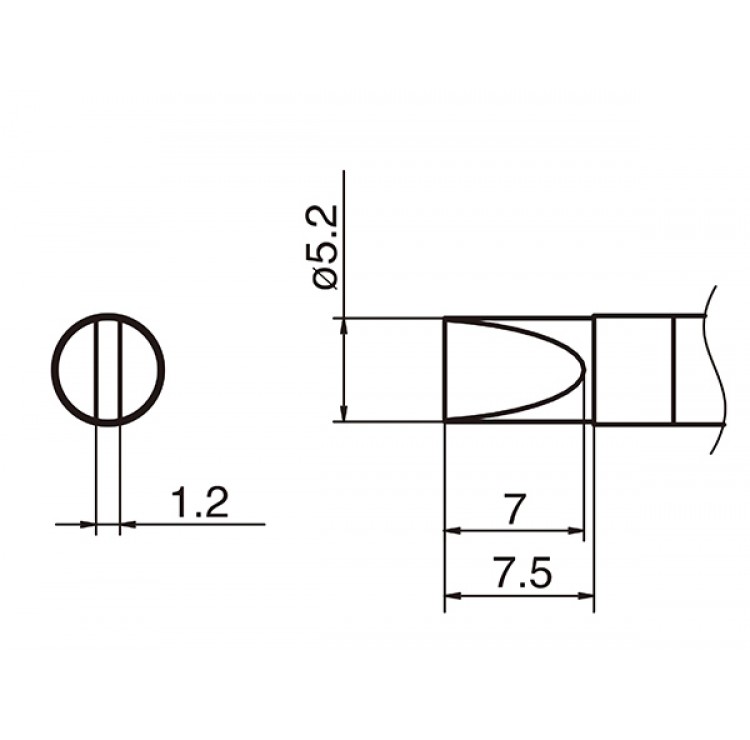

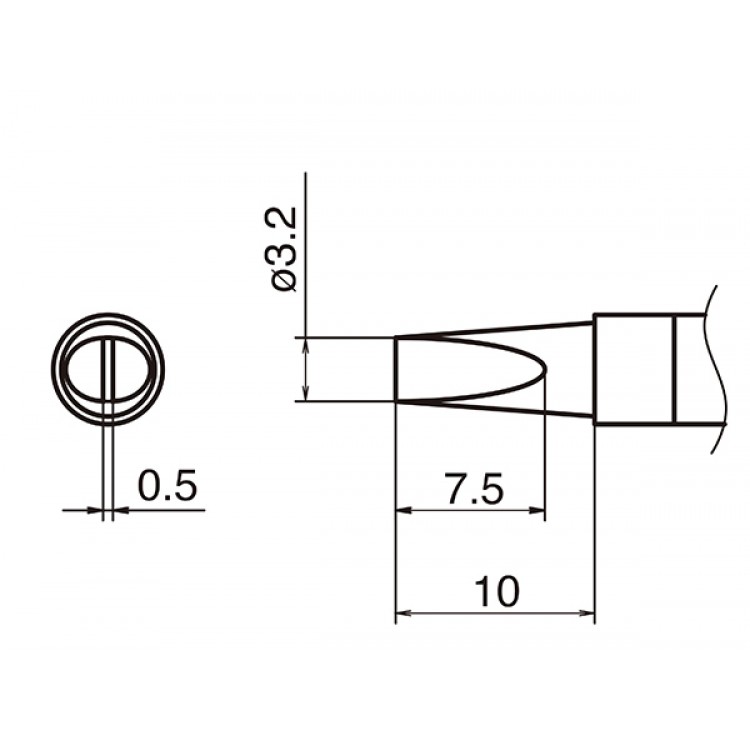

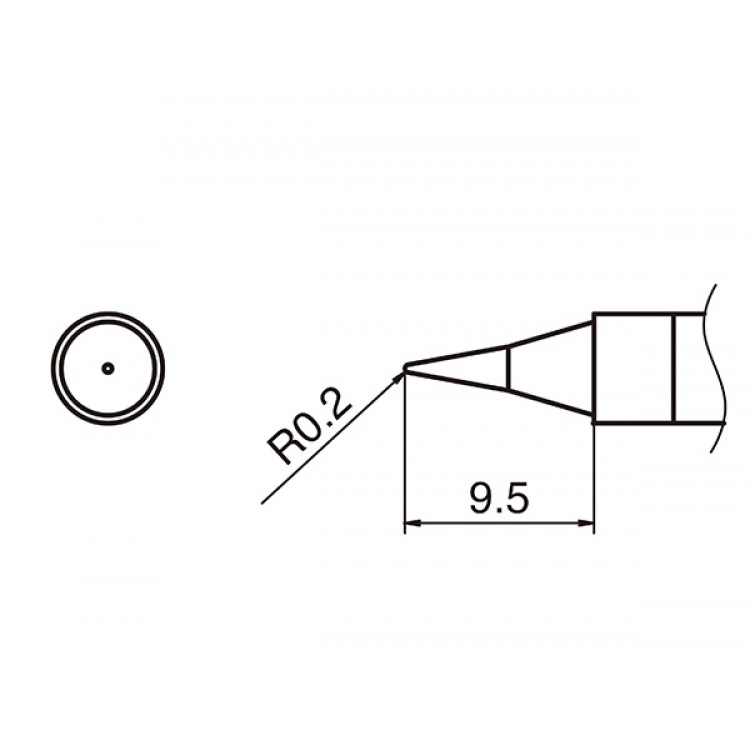

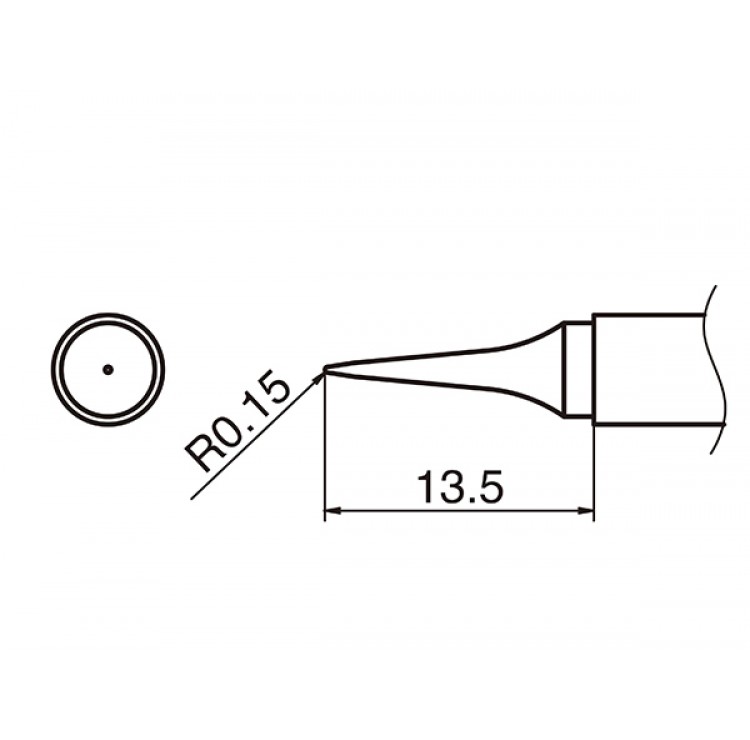

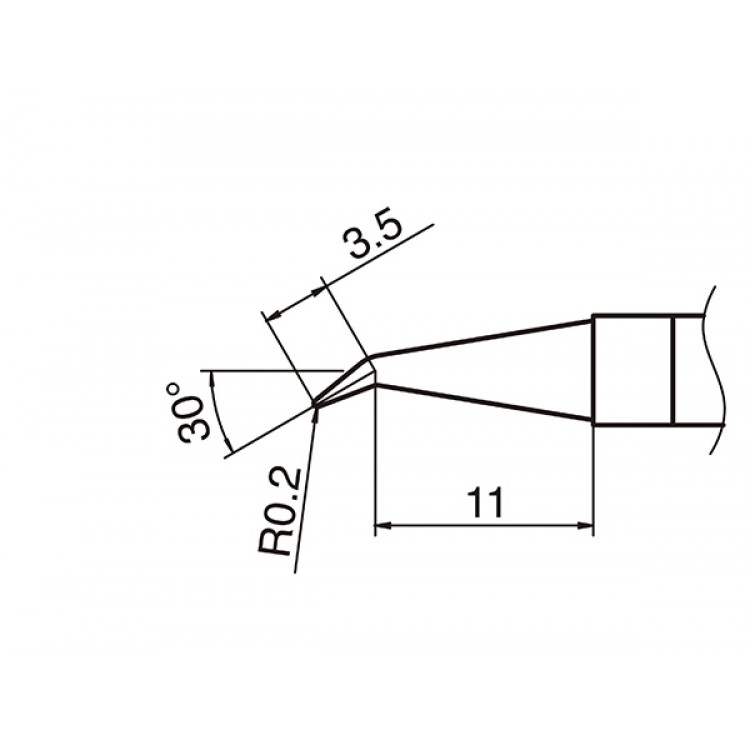

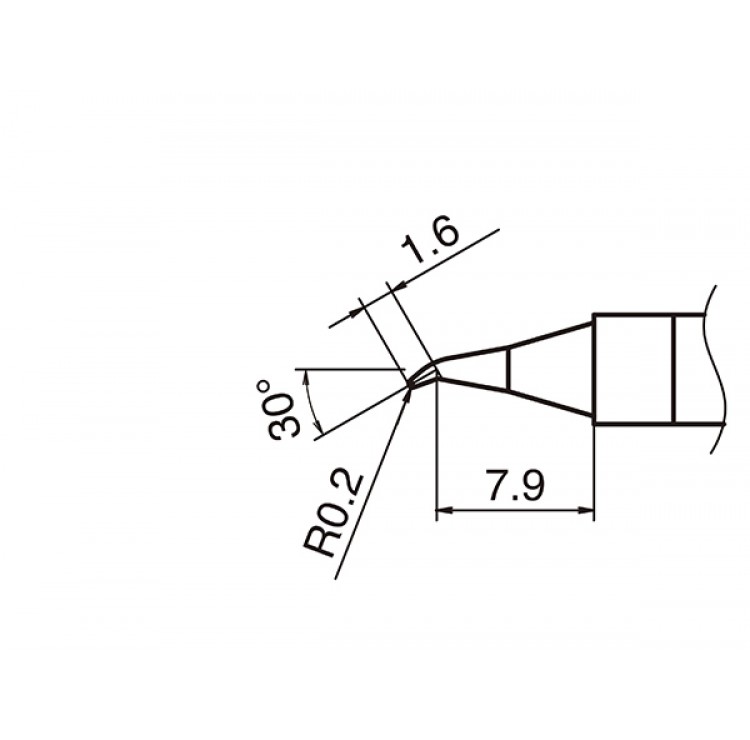

Soldering Tip / Nozzle

T36 Series

Replacement Parts

| Part No. | Name | Specifications | ||

|---|---|---|---|---|

| FN1101-81 | FN-1101 Soldering iron | Buy | |

| FH210-81 | FH-210-81 Iron holder | Buy | |

| FT401-81 | FT-401 Tip cleaner | Buy | |

| A1561 | A1561 Tip Cleaning wire | Buy | |

| B5208 | B5208 Transformer | Buy | |

| B5213 | B5213 Solder Scatterproof Cover | Buy | |

| B5214 | B5214 Tip removing attachment | Buy | |

| B5215 | B5215 Holder for iron receptacle | Buy | |

| B5216 | B5216 Iron receptacle with screw | Buy | |

| B2791 | B2791 Retaining clip | Buy | |

| B5217 | B5217 Nipple with Sealing valve | Buy | |

| B5218 | B5218 Sealing valve | Buy |

Option

| Part No. | Name | Specifications | ||

|---|---|---|---|---|

| FN1102-81 | FN1102 N2 Soldering Iron | Buy | |

| B5210 | B5210 Interface card USB | Buy | |

| B5211 | B5211 Interface card RS232C | Buy | |

| B5212 | B5212 Interface card LAN | Buy | |

| B2300 | Heat Resistant Pad | Buy |

| Category | Title |

|---|---|

| Top Tips | Top Tips for Successful Soldering and De-Soldering Processes |

| Weight | 3.251 kg |

|---|