No products in the basket.

HAKKO, Hot air stations, Product catalogue, Rework stations, Shop by brand, SMD rework

FR-811 Advanced Hot Air Rework Station

SKU: HFR811-16

Availability:

In stock

Professional Hot Air Rework Station with USB connection

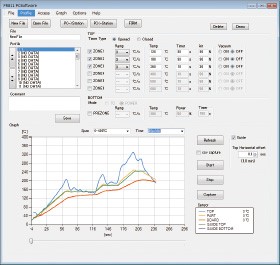

Possible to make full-scale thermal profiles with 6-zone hot air and a bottom heater (optional).

Possible to measure and record temperature of components and PWB with type K thermocouple.

The dedicated software to link a station and a computer for easy and quick settings.

Easy data transfer through an USB cable

£1,754.40 Excl. VAT

In stock

Introducing a high-spec hot air rework station

with excellent cost performance

Operate on a computer with the dedicated software

The functions needed for SMD rework are in a compact body

A low cost SMD rework can be assembled with FR811, dedicated software and options.

| Possible to make full-scale thermal profiles with 6-zone hot air and a bottom heater. | |

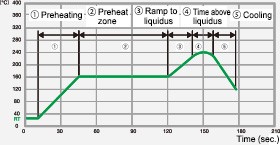

| A basic thermal profile is composed of the 5 parts shown above. FR811 Advanced Hot Air Rework Station can provide 6 zones in which temperature, time, and air flow are controlled. Therefore FR-811 can make a full-scale thermal profile which is close to reflow profiles made by a reflow oven. |  |

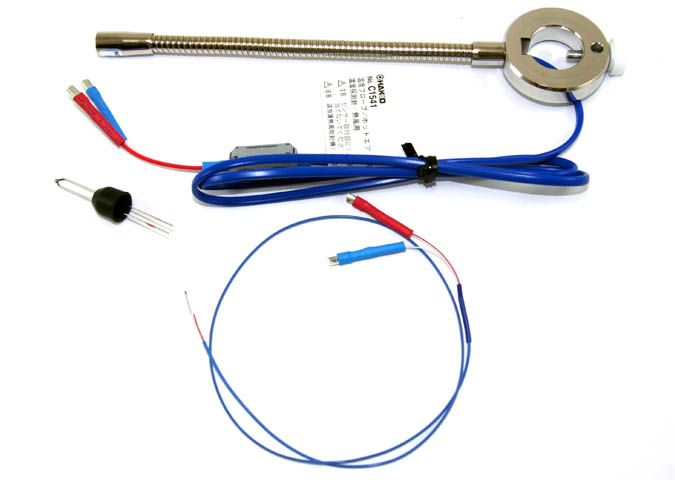

| Record thermal data | |

| By connecting a thermocouple included with FR811 Advanced Hot Air Rework Station, the temperature of the component or circuit board can be measured and recorded. In addition, if “TC LINK” is set, the heater output can be automatically controlled so that the temperature of the thermocouple attached to the component or circuit board follows the set profile. |  |

| Operation on a PC for various settings | |

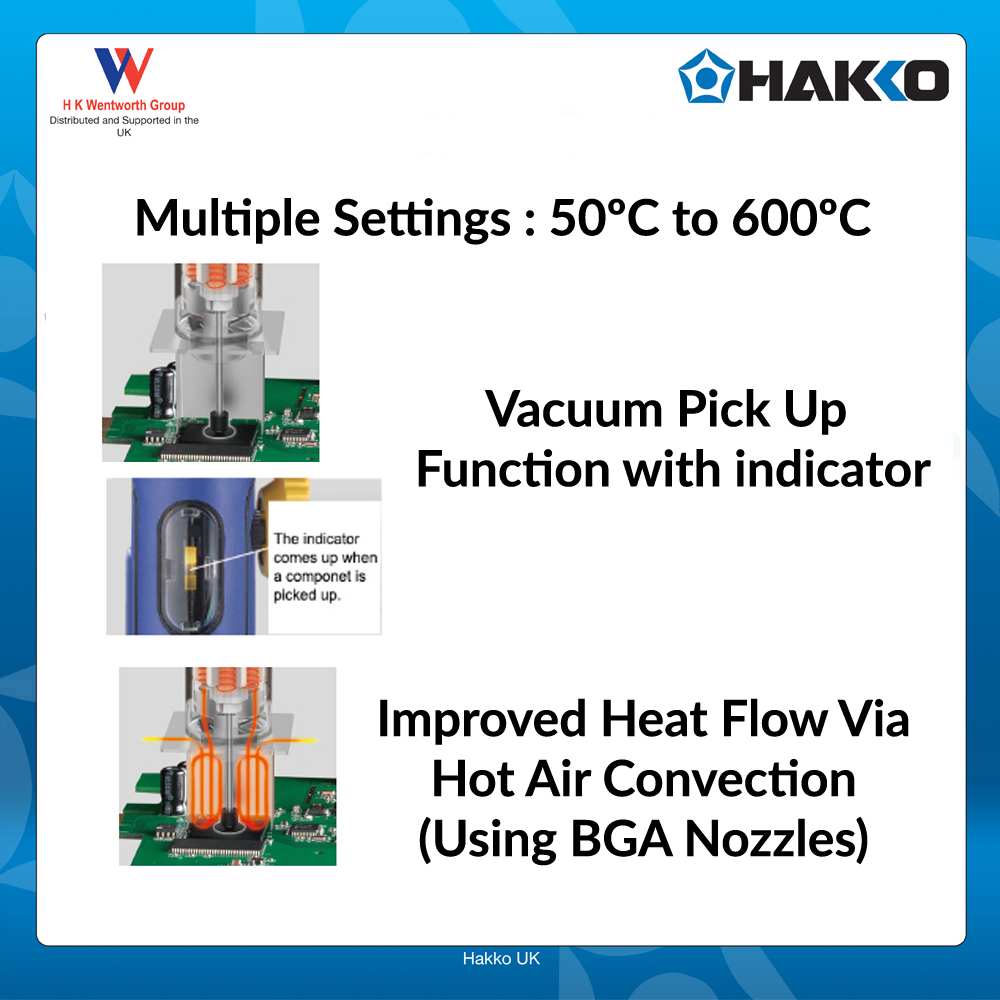

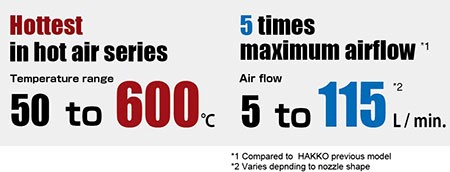

High power and large volume hot air for quick removal of components

A tool that can provide powerful hot airflow for repairing high heat capacity circuit boards that require high blow volume and high output, and sufficient hot airflow for appropriate blow volume and high output for high-density mounting substrates.

New user friendly functions for SMD rework

Interface designed for intuitive operation. Possible to link to a PC

Use conventional HAKKO nozzles

Align the projection part, attach the conventional nozzle to the heater pipe.

*The heater pipe of HAKKO FR810 (discontinued) has two projection parts. In order to use the conventional nozzle, put the conversion adaptor on the heater pipe that was included in your purchased HAKKO FR810 as one of standard accessories.

Click here for details.

Simple nozzle removal and easy maintenance

Nozzle can be changed quickly when working with a wide range of components. Conventional HAKKO nozzles can be used by using a special conversion adapter (option).

Heater replacement is also simple.

| Quick-change N51 nozzles | Simple heater replacement |

|  |

| Simple, tool-free removal and attachment. | Simply remove four screws to replace heater. |

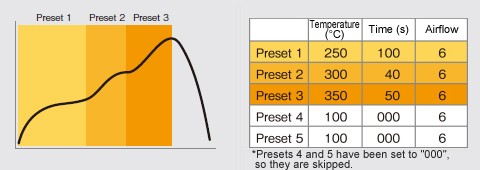

Can also create a simple thermal profile (same as HAKKO FR810B)

Timer function

Timer function is to control the time of operation.

This can help to prevent parts from overheating and can improve the overall quality of rework.

Chain presets function for making a simple thermal profile

The chain presets function is to make a simple thermal profile by combining several preset conditions. (Up to 5 steps)

This can improve work efficiency a lot by standardizing work time, avoiding overheating, improving repeatability of operation, and making difficult rework jobs easy.

Auto sleep and auto shutoff features

To ensure safety and conserve power, when the handpiece is placed in the handpiece holder, the auto sleep function will be activated and it will start cooling automatically.

If the handpiece has not been removed from the handpiece holder (e.g. Using it in a rework fixture) and it has been idle for 30 minutes, auto shutoff function will be activated. It will be automatically powered off. Access to settings can be restricted by the password function.

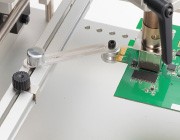

Assembly of a low-cost SMD rework system

A low cost rework system can be assembled with a bottom heater, a grip fixture, and a board holder.

|  |  |

| Grip Fixture L A board holder can be easily attached to the large baseplate | Grip Fixture M Recommended if a bottom heater is not required or in case of use of a bottom heater other than the dedicated model for FR811. | C5024 A dedicated bottom heater for FR811 Equipped with carbon heaters. Heating area is divided into 2 sections. |

|  |  |

| C5027 Board Holder Makes it easy to set and remove a P.W.B and to make fine adjustments after setting. | Board Clip Accepts even irregular-shaped PWB. | Board Support Unit Supports PWB from underneath to minimize warping. |

- FR811 Station with handpiece and Instructions,

- Power Cord (B2425)

- Grip stand assembly (C5033)

- Vacuum pipe control knob (with screw) (B3023)

- Suction Pads (qty 2 each of Ø3 mm (A1520), Ø5 mm (A1439), Ø7.6 mm(A1438)),

- USB cable (B5129)

- Software (CD-ROM)

- Thermocouple, (B5128)

- Heat resistant pad, (B2300)

- Temperature distribution chart.

FR-811 Specifications:

| Model No. | FR811 |

| Power consumption | AC100V:700W AC110V:840W AC120V:820W AC220V:1,100W AC230V:1,200W AC240V:1,300W |

| Temperature range | 50 to 600ºC |

| Power consumption | 30W |

| Air flow | 001-100% (5 to 115L/min.) |

| Dimensions | 160(W)×145(H)×220(D)mm |

| Weight | 1.5kg |

| Power consumption | AC100V:670W AC110V:810W AC120V:790W AC220V:1,070W AC230V:1,170W AC240V:1,270W |

| Total length | 250mm |

| Weight | 180g |

Recommended / Optional Extras FR-811

| Image | Part Number | Description | Availability |

| C5024 | Underboard Heater | Buy Now |

| C5027 | Board Holder | Buy Now |

| C5028 | Grip Fixture S | Buy Now |

| C5029 | Grip Fixture L | Buy Now |

| B5059 | Adaptor / for fixture (C1392B) | Buy Now |

| B5127 | Thermocouple 0.1mm | Buy Now |

| B5130 | Heat Resistant Tape | Buy Now |

| FG-100B C1541 | Thermometer Hot Air Station Probe | Buy Now Buy Now |

| Image | FT640 / FT641 | Tweezers | |

| 106 Series | Wire Processing Tools | Buy Now |

| SMF012P | Flux Pen | Buy Now |

| FLU400DB | Flux Cleaning Solvent | Buy Now |

| Various | Desolder Braid | Buy Now |

| FA-430 | Fume Extractor and Air Purifier | Buy Now |

| 393 | Vacuum Pump Pick Up Tool | Buy Now |

| 394 | Battery Powered Vacuum Pump Pick Up Tool | Buy Now |

| FR-830 | Under Board Heater | Buy Now |

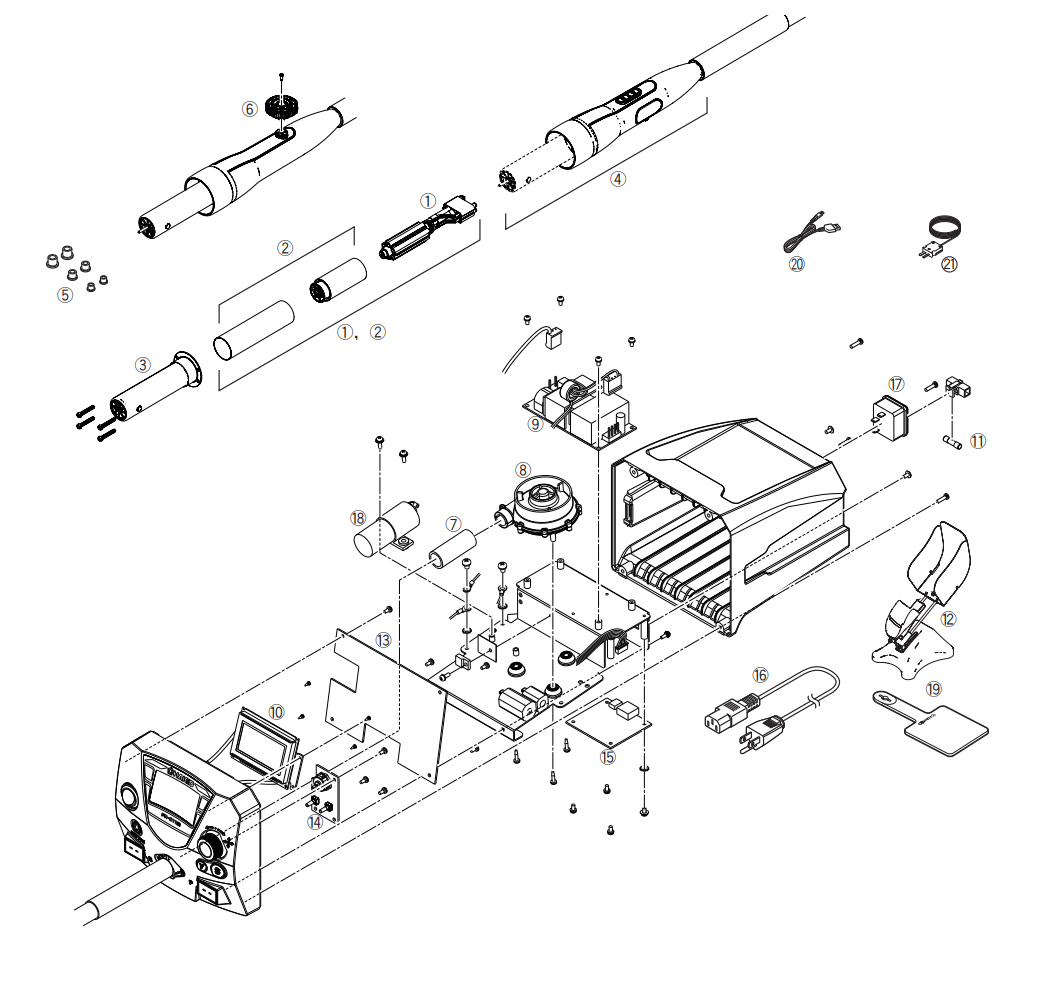

| Ref. | Image | Part Number | Description | Availability |

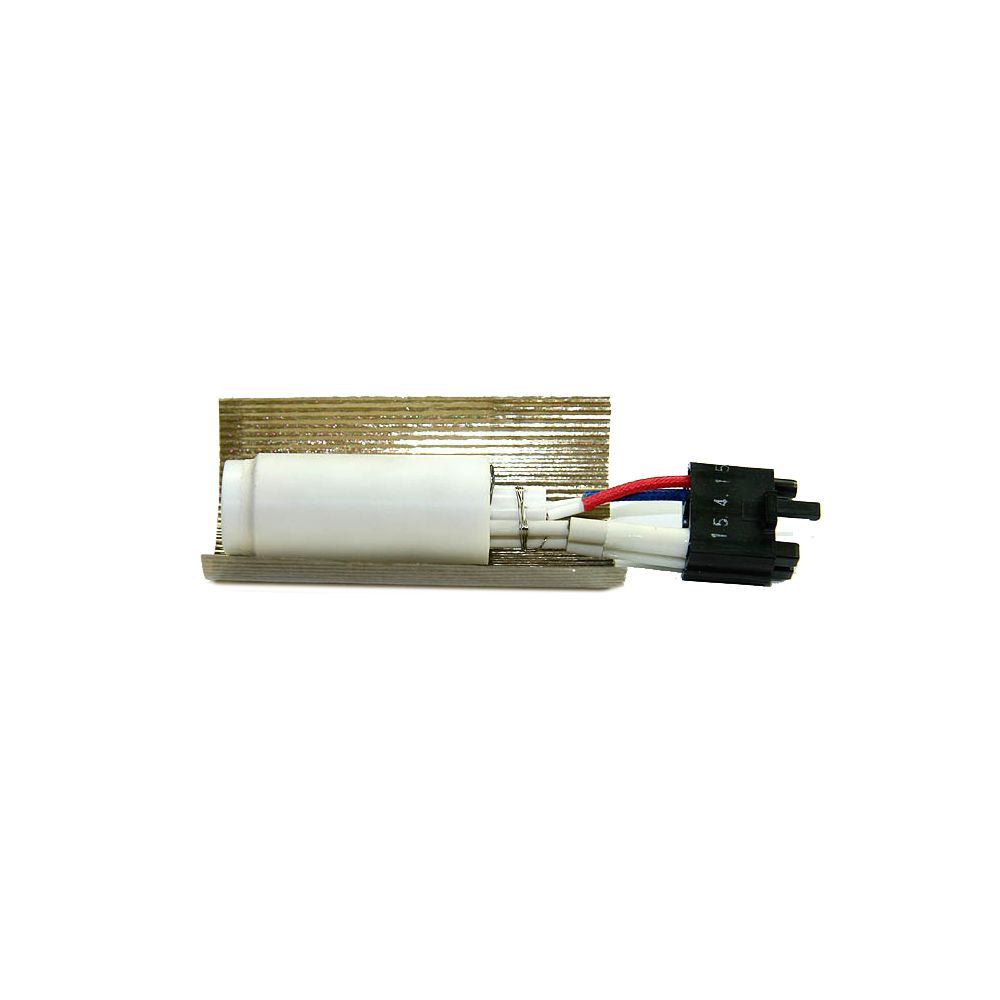

| 1.&2. |  | A5007 | Heating Element Assembly | Buy Now |

| 1. |  | A5024 | Heating Element | Buy Now |

| 2. |  | B5049 | Mica + Cover | Buy Now |

| 3. |  | B5045 | Heater cover Pipe | Buy Now |

| 4. |  | B5091 | Handle with Cord Assembly | Buy Now |

| 5. |    | A1520 A1439 A1438 | Vacuum Pick Up Pad 3mm Vacuum Pick Up Pad 5mm Vacuum Pick Up Pad 7.6mm | Buy Now Buy Now Buy Now |

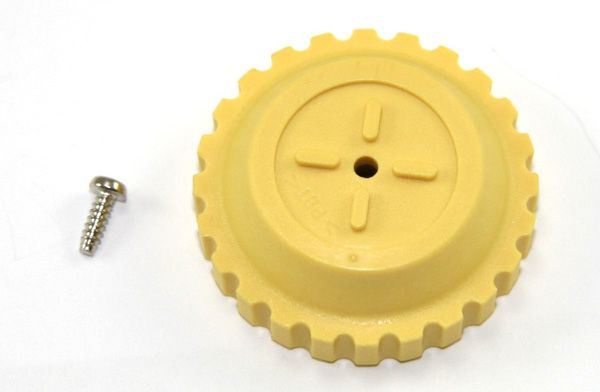

| 6. |  | B3023 | Vacuum Pipe Adjustment Knob | Buy Now |

| 7. |  | B5043 | Joint Hose | Buy Now |

| 8. |  | B5052 | Fan | Buy Now |

| 9. |  | B5053 | Power Unit | Buy Now |

| 10. |  | B5095 | P.W.B for LCD | Buy Now |

| 11. |  | B5060 | Fuse 250V 6.3A | Buy Now |

| 12. |  | C5033 | Grip Stand Assembly | Buy Now |

| 13. |  | B5094 | P.W.B for Control | Buy Now |

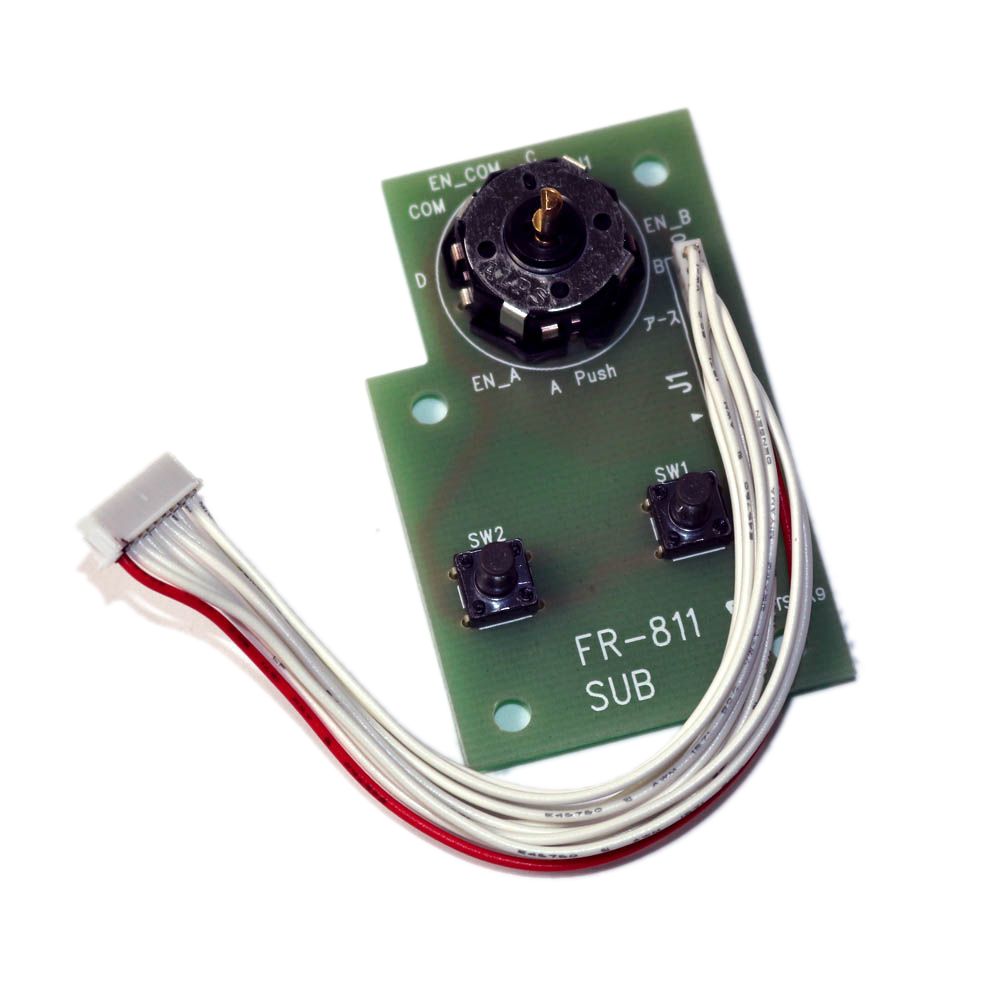

| 14. |  | B5096 | P.W.B for encoder Switch | Buy Now |

| 15. |  | B5097 | P.W.B for USB | Buy Now |

| 16. |  | B2425 | Power Lead (British Plug) | Buy Now |

| 17. |  | B2384 | Power Inlet | Buy Now |

| 18. |  | B5092 | Pump | Buy Now |

| 19. |  | B2300 | Heat Resistant Pad | Buy Now |

| 20. |  | B5128 | Thermocouple 0.2mm with connector | Buy Now |

| 21. |  | B5129 | USB Cable | Buy Now |

| Weight | 2.6987 kg |

|---|