No products in the basket.

Cleaning / polishing stations, FT-700, FT-700, HAKKO, Product catalogue, Shop by brand, Soldering related equipment

FT-700 Soldering Tip Cleaner and Polisher

SKU: HFT700-15

Availability:

In stock

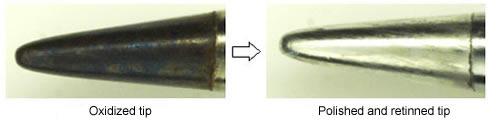

Soldering tip polisher best suited for the removal of oxidation on soldering tips

Oxidized films firmly sticking to tips are removed using a supplied brush

It prevents the shortening of service life of tips caused by oxidation

£261.85 Excl. VAT

In stock

Features

| “Maintenance kit for oxidized soldering tips” Especially suitable for soldering tips oxidized by Lead-free solder and high temperature solder By using the brush and accessory “Chemical Paste”HAKKO FS-100: | |

| Carbide and oxide can be removed without causing damage to the soldering tip | |

| Diamnonium phosphate is not included | |

| Power saving with 3 watts low consumption. | |

|

Usage/Applications

| Cleaning procedure | ||

Oxidized tip |  |  Cleaning is now completed. | ||||

Remove carbide and oxide. |   Tin the tip. (remove oxide) |    Clean off chemical paste from the tip surface. |   Tin the tip with solder. | |||

Repeat the process twice or more until oxide is completely removed. | ||||||

| NOTE: | When the tip temperature is over 400°C, even if the oxidation film is removed by “HAKKO FT-700 tip polisher”, the tip can turn to be oxidized quickly again. |

| When carbide and oxide cannot be removed by the above procedure |

| When carbide and oxide are hard, they sometimes cannot be removed even by the HAKKO FT-700. In this case, first use the brush which included in the unit as one of accessories and clean the tip by the above procedure. |

| NOTE: | When the brush is used, small scratches may be produced on the iron plating surface of the tip. Do not always use the brush, but use only when oxidation cannot be removed by cleaning with HAKKO FT-700. | |

Packing List

| Part No. | Packing List |

| No.FT700 | HAKKO FT-700 Tip Polisher, HAKKO FS-100 Paste, Brush: 1pc each |

Specifications

| Model No. | FT-700 |

|---|---|

| Power consumption | 3W (100V), 4.5W (110 to 120V, 220 to 240V) |

| Dimensions | 70(W)×54(H)×101(D)mm |

| Weight | 0.65kg |

| Amount | 10g |

|---|---|

| Ingredients | Flux, tin(Sn) 50wt%(each) |

Replacement Parts

| Part No. | Name | Specifications | ||

|---|---|---|---|---|

| FS-100 | HAKKO FS-100 paste | Buy | |

| B3051 | Brush | Buy | |

| B3052 | Polishing brush (qty 2) | Buy |

| Weight | 0.8447 kg |

|---|

You may also like…

- Shop by brand, HAKKO, Product catalogue, Accessories, FT-700, Spare parts, Replacements for accessories, Other parts, FT-700, Replacement cleaning / consumable products, Cleaning stations, FT-700, Wire / brushes

B3051 Tip Cleaning Brush

Shop by brand, HAKKO, Product catalogue, Accessories, FT-700, Spare parts, Replacements for accessories, Other parts, FT-700, Replacement cleaning / consumable products, Cleaning stations, FT-700, Wire / brushes

Shop by brand, HAKKO, Product catalogue, Accessories, FT-700, Spare parts, Replacements for accessories, Other parts, FT-700, Replacement cleaning / consumable products, Cleaning stations, FT-700, Wire / brushesB3051 Tip Cleaning Brush

0 out of 5(0)B3051 Tip Cleaning Brush for cleaning and polishing Sodler Iron Tips

SKU: HB3051 - Shop by brand, HAKKO, Product catalogue, Spare parts, Replacement cleaning / consumable products, Sponges / polishers, Cleaning maintenance, Cleaning / polishing stations, FS-100, Other

FS100-01 Solder Tip Cleaning Paste

Shop by brand, HAKKO, Product catalogue, Spare parts, Replacement cleaning / consumable products, Sponges / polishers, Cleaning maintenance, Cleaning / polishing stations, FS-100, Other

Shop by brand, HAKKO, Product catalogue, Spare parts, Replacement cleaning / consumable products, Sponges / polishers, Cleaning maintenance, Cleaning / polishing stations, FS-100, OtherFS100-01 Solder Tip Cleaning Paste

0 out of 5(0)Chemical paste best suited for the removal of oxidation on soldering iron tips

Also used for retinning of soldering tipsSKU: HFS100-01 - Shop by brand, HAKKO, Product catalogue, Spare parts, Replacements for accessories, Other parts, FT-700, Replacement cleaning / consumable products, Cleaning stations, FT-700

B3052 Replacement Polishing Brushes for FT-700