No products in the basket.

HAKKO, Product catalogue, Shop by brand, Soldering equipment, Soldering stations

FX-100 Induction Heating Soldering Station

SKU: HFX100-15

Availability:

Low stock – Order soon

FX-100 provides the heat to the tip effectively by Induction heater

In addition, it allows more efficient heat supply with power assist of our unique technology.

No calibration is required.

£608.99 Excl. VAT

Low stock – Order soon

The FX100-15 Induction Heating Soldering Station or IH system transforms high-density micro-soldering with the heat power it generates.

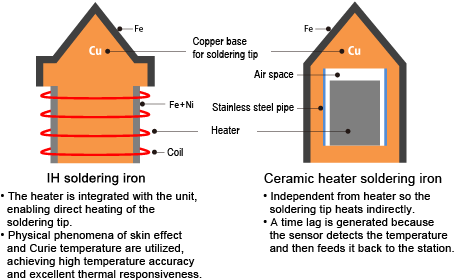

What is IH (High-Frequency Induction Heating)

Unlike resistance-based heating systems that control temperature by turning heater power on and off via a sensor, with an induction heating system the soldering tip itself produces heat and maintains a constant temperature, enabling a small soldering tip to handle high thermal capacity, high-density substrates.

|

With the FX100-15 Induction Heating Soldering Station or IH system, controlling the temperature of the soldering iron is easy

Temperature setting control of the soldering iron is easier as the temperature is fixed with the various models in the soldering tip line up, unlike with conventional temperature setting systems. Whatever temperature is selected,it can be displayed on the LCD panel with simple button operations.

HAKKO FX1001 Soldering Iron (standard): 350°C, 400°C, 450°C

HAKKO FX1002 Soldering Iron (optional): 350°C, 400°C

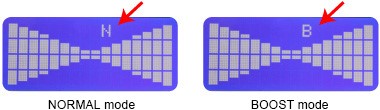

When a slight drop in heat capacity is detected…

When there is a drop in heat capacity while soldering, the actual temperature of the tip can be raised slightly by selecting BOOST mode, improving workability.

Two types of soldering irons enable handling of both “high heat capacity, high-density circuit boards” and “soldering under a microscope”

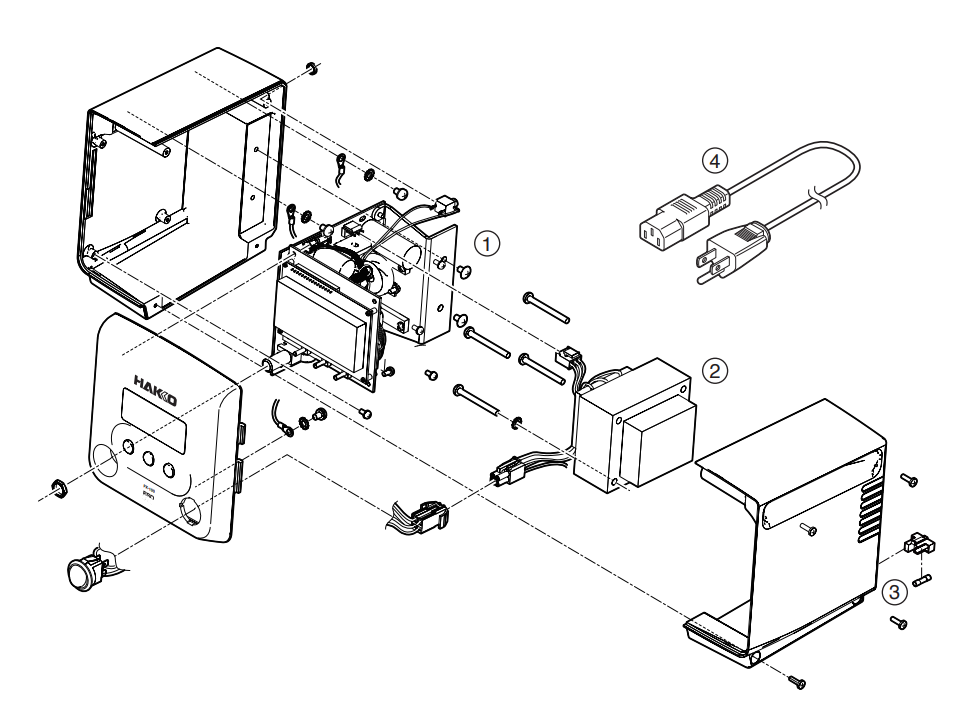

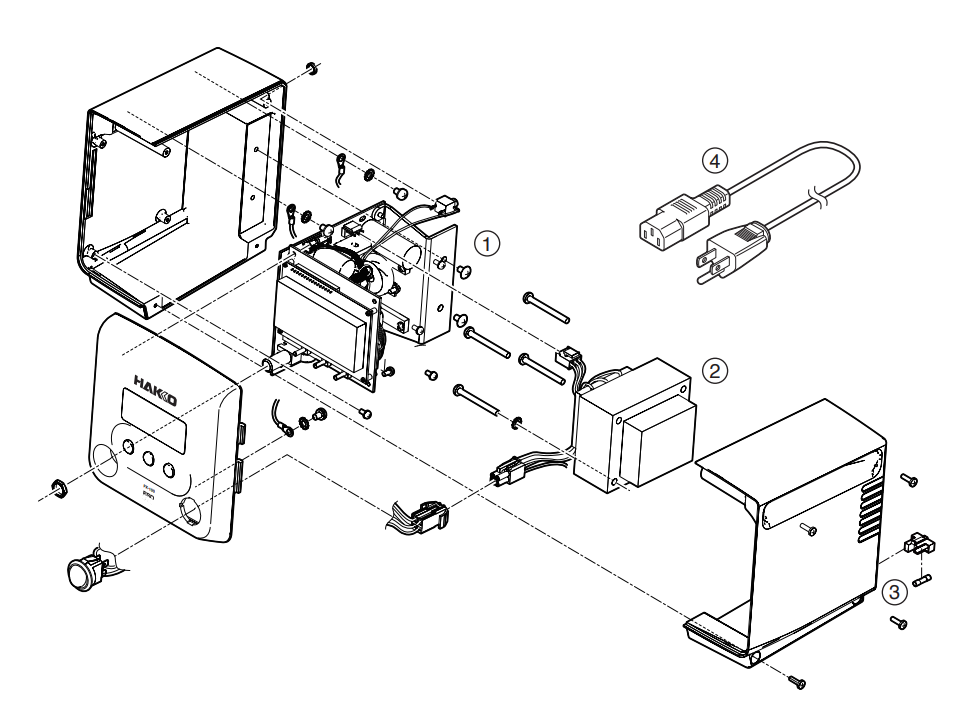

| Part No. | Packing list |

| No.FX-100 |

|

Soldering Tip / Nozzle

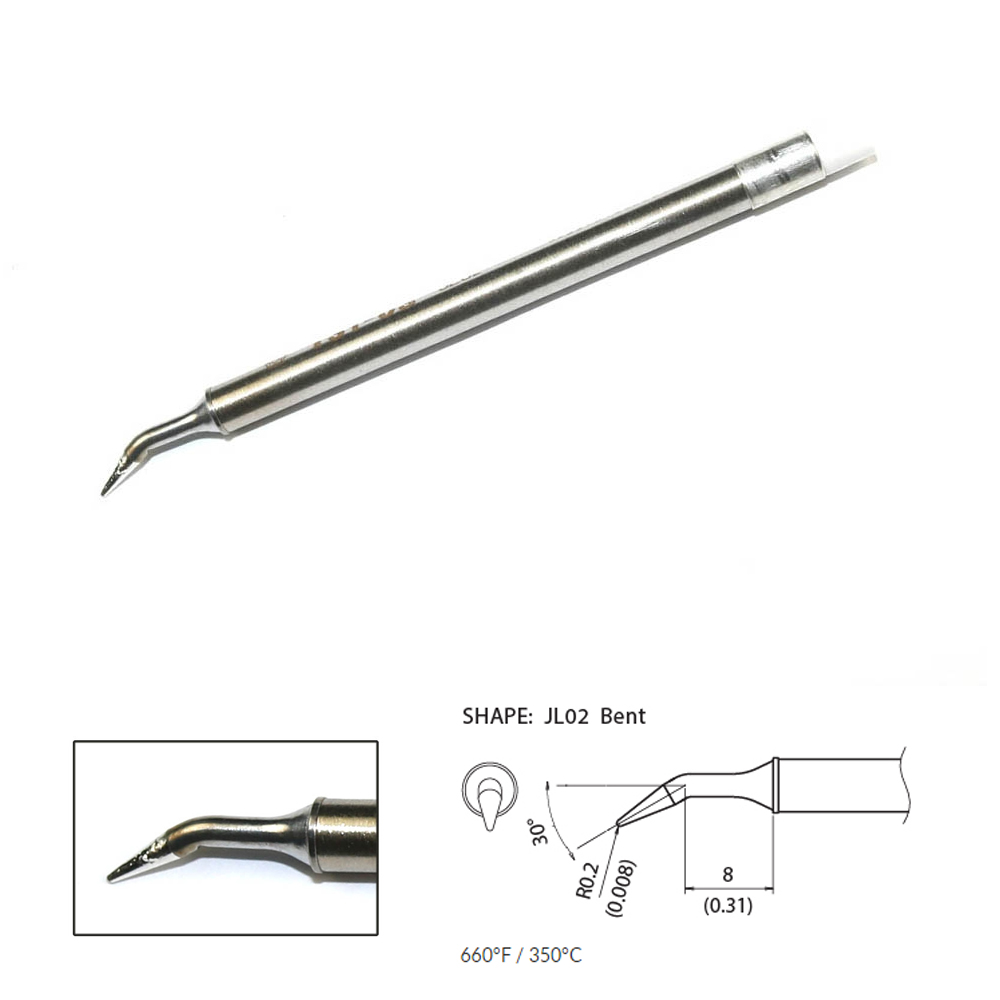

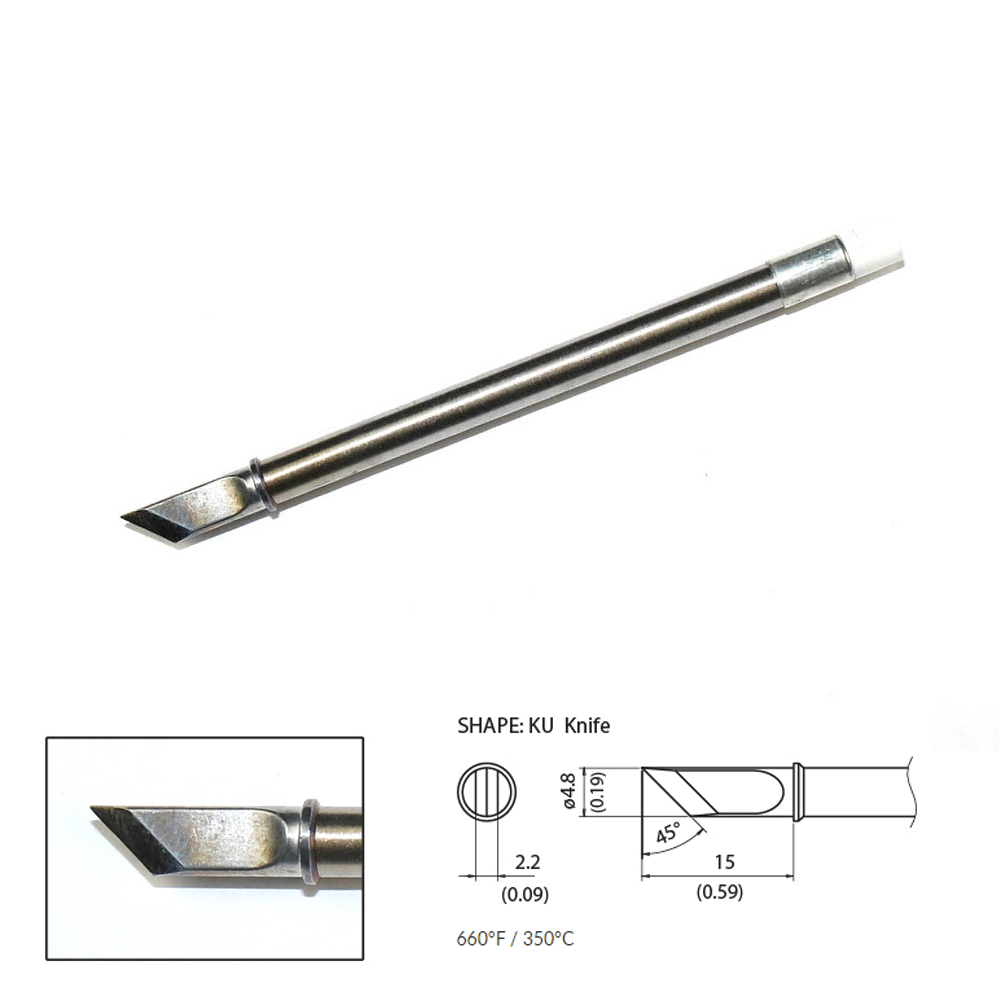

T31 Series

Shape BC/C

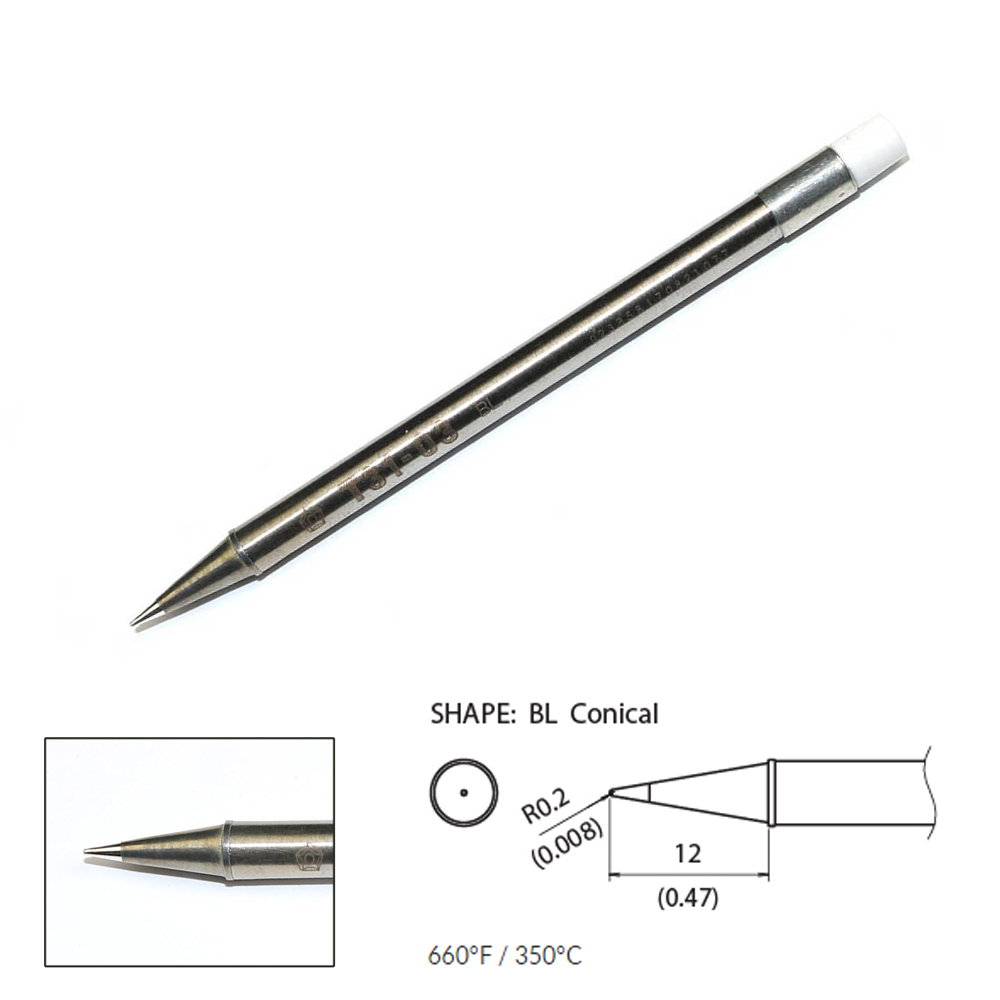

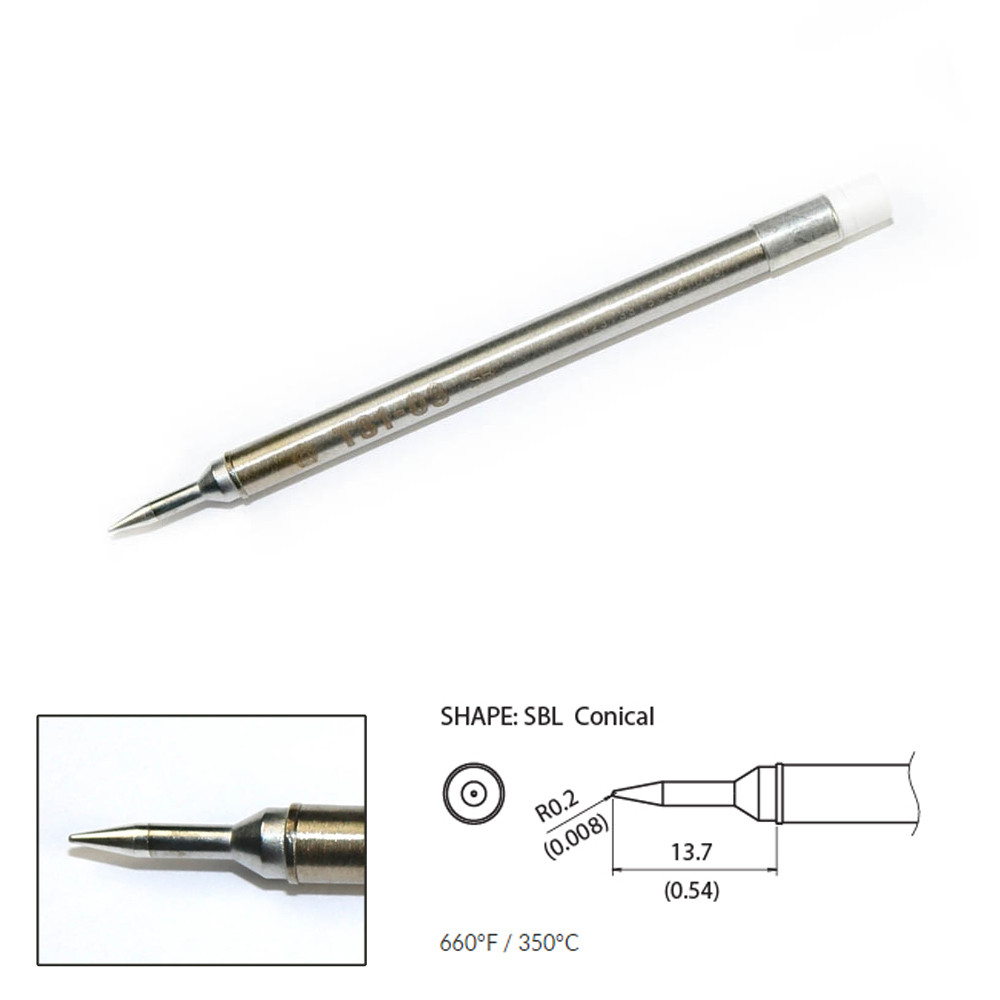

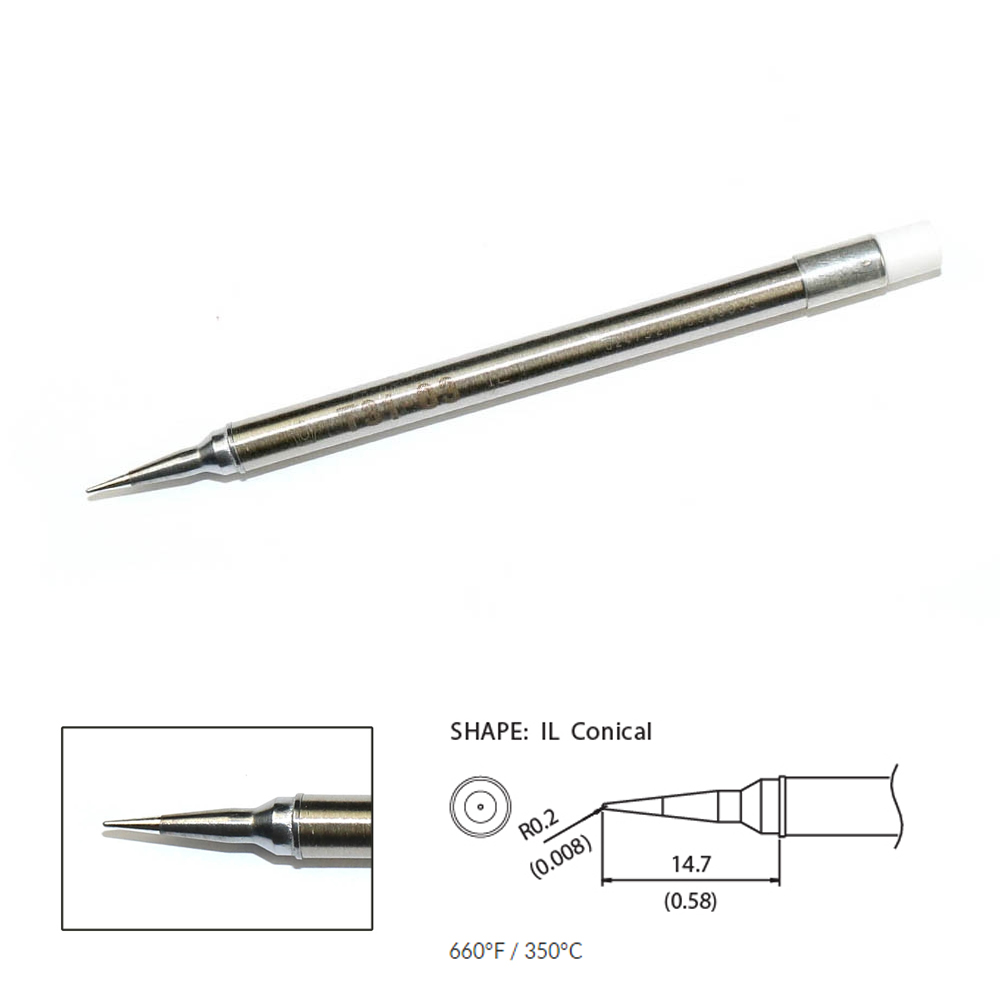

Shape B

Shape D

Shape I

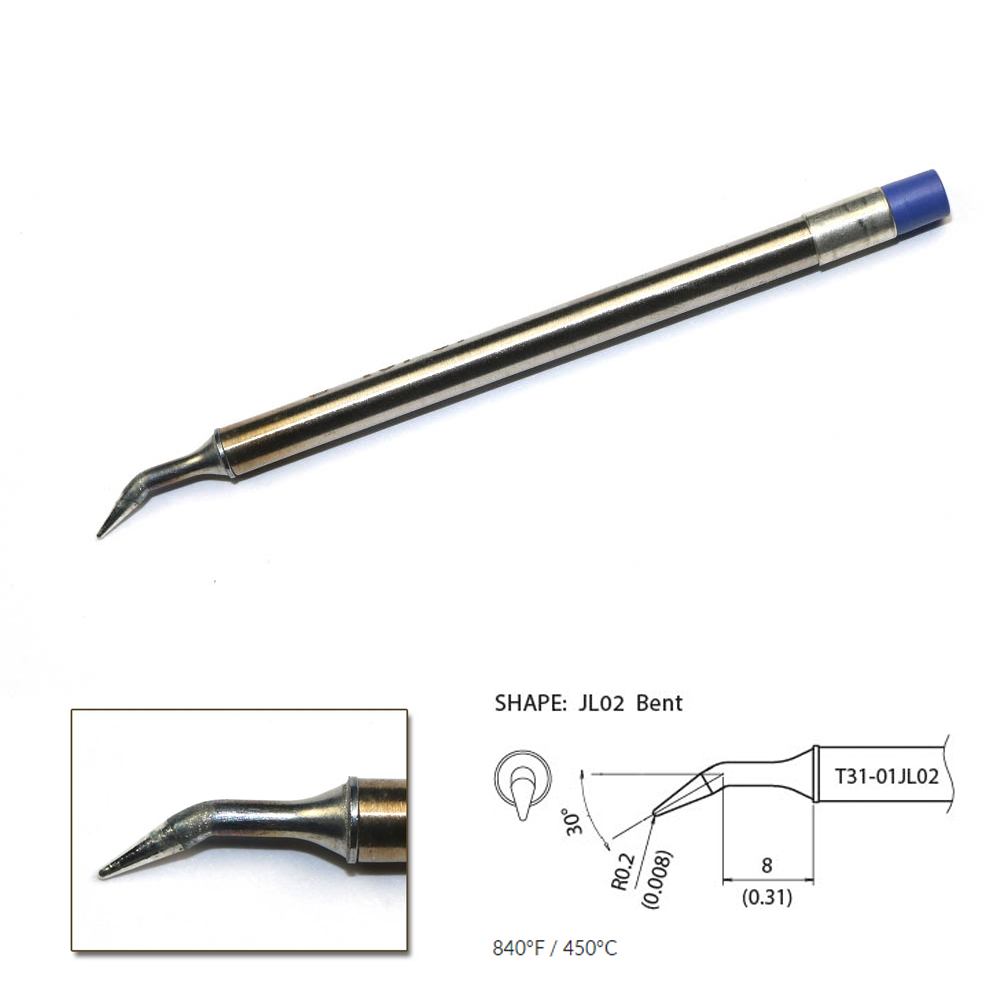

Shape J

Optional / Recommended Extras

| Part Number | Description | ||

| 1. FX1003-81 | FX1003-81 Micro Tweezers (Tweezers Only) | Buy |

| 1. FX1003-82 | FX1003-82 Micro Tweezers (Conversion Kit) | Buy |

| 1. FX1002-81 | Micro-Soldering Iron Hand piece | Buy |

| 2. FX1002-82 | Micro-Soldering Iron Conversion Kit | Buy |

| 3. B5180 | Green Sleeve Assembly for FX1002 | Buy |

| 4. FG-100B | Tip Thermometer | Buy |

| 5. B2756 | Tip Holder | Buy |

| 6. 611-1 | Solder Wire Holder | Buy |

| 7. 599B | Tip Cleaner | Buy |

| 8. B3474 | Rubber Tip Cleaner | Buy |

Replacement Parts FX100

| Part Number | Description | ||

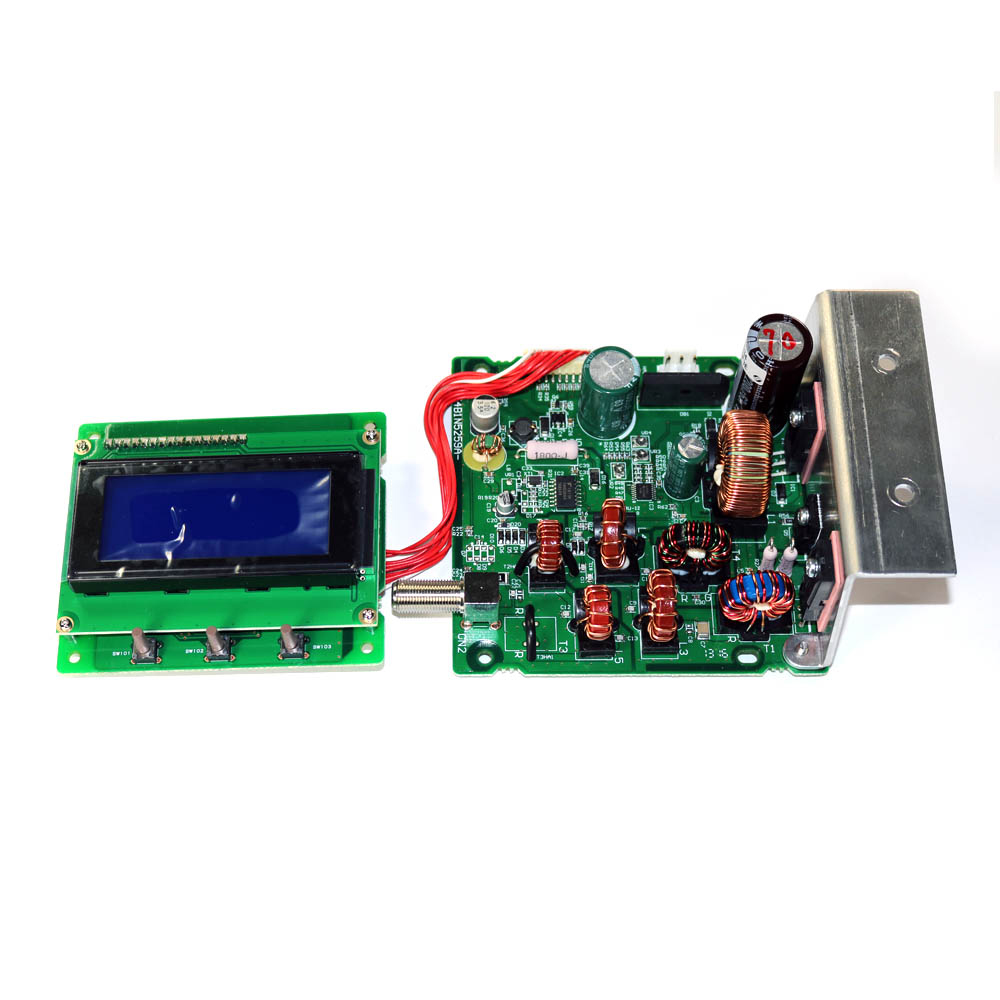

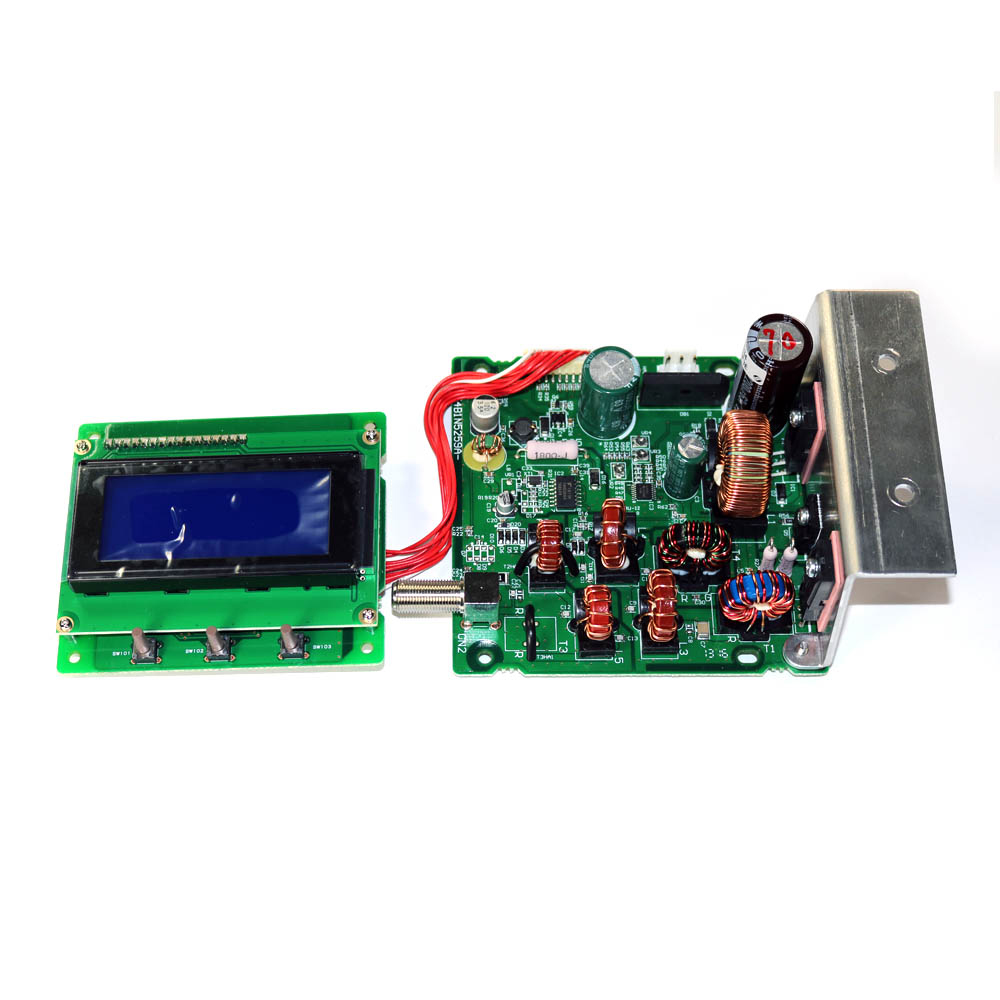

| 9. B5002 | P.W.B Circuit board | Buy |

| 10. B5005 | Transformer | Buy |

| 11. B2987 | Fuse | ||

| 12. B2425 | Power Cord (B.S) | Buy |

Replacement Parts FX1001

| Part Number | Description | ||

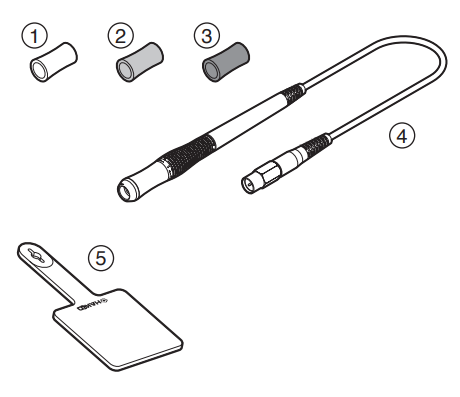

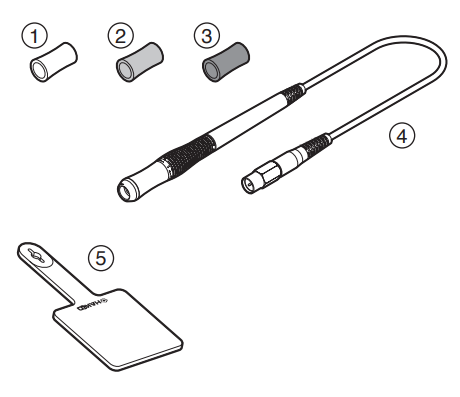

| 1. B5006 | Sleeve Assembly Yellow | Buy |

| 2. B5007 | Sleeve Assembly Green | Buy |

| 3. B5008 | Sleeve Assembly Grey | Buy |

| 4. FX1001-81 | FX1001 Soldering Iron | Buy |

| 5. B2300 | Heat Proof Mat | Buy |

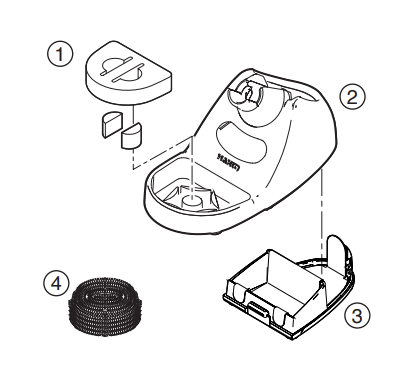

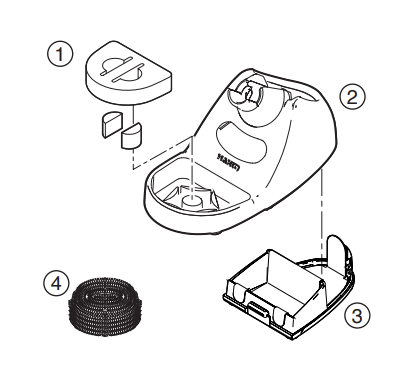

Replacement Parts FH800

| Part Number | Description | ||

| FH800 | Full Iron Holder | Buy |

| 1. B5038 | Cleaning Sponge | Available to Buy: Contact us | |

| 2. B5009 | Holder Top | Available to Buy: Contact us | |

| 3. B3751 | Holder Base | Available to Buy: Contact us | |

| 4. A1561 | Cleaning Wire | Buy |

| Category | Title |

|---|---|

| Top Tips | Top Tips for Successful Soldering and De-Soldering Processes |

| Weight | 4.074 kg |

|---|

You may also like…

- Shop by brand, HAKKO, Product catalogue, Soldering iron tips, T9 series, T16 series, Desoldering nozzles, N3 series, Hot air nozzles, N4 series, Accessories, FX-951, FX-952, Spare parts, Replacements for units, Replacements for soldering stations, FM-206, FX-951, FX-952, Replacements for desoldering stations, FM-206, Replacements for rework stations, FM-206

B2756 Tip Holder Tray

Shop by brand, HAKKO, Product catalogue, Soldering iron tips, T9 series, T16 series, Desoldering nozzles, N3 series, Hot air nozzles, N4 series, Accessories, FX-951, FX-952, Spare parts, Replacements for units, Replacements for soldering stations, FM-206, FX-951, FX-952, Replacements for desoldering stations, FM-206, Replacements for rework stations, FM-206

Shop by brand, HAKKO, Product catalogue, Soldering iron tips, T9 series, T16 series, Desoldering nozzles, N3 series, Hot air nozzles, N4 series, Accessories, FX-951, FX-952, Spare parts, Replacements for units, Replacements for soldering stations, FM-206, FX-951, FX-952, Replacements for desoldering stations, FM-206, Replacements for rework stations, FM-206B2756 Tip Holder Tray

Tip tray to hold the T9, T15, T16, T22, T30, T31, T33, T35, N3, N4 series tip, for use with the FM-206/203 and FX-951/100.

SKU: HB2756