No products in the basket.

HAKKO, Product catalogue, Shop by brand, Soldering equipment, Soldering stations

DISCONTINUED FX888D-SET1 Soldering Station and T18 Soldering Tip Set DISCONTINUED

SKU: HFX888D_SET1

Availability:

Available for order*

DISCONTINUED

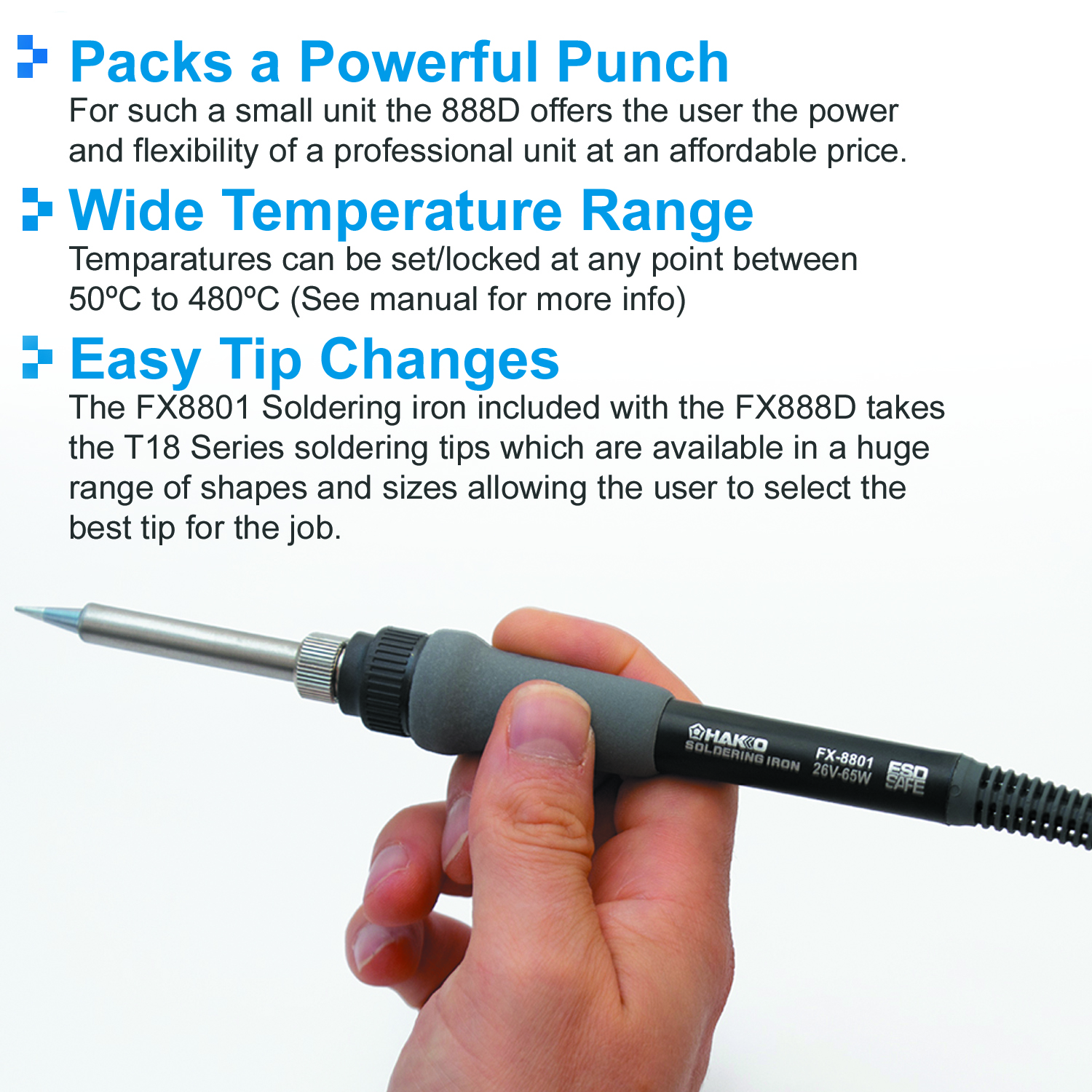

Compact Digital Soldering Station with Soldering Iron, Stand and 6 Tip Set included.

Adjustable temperature control with Temperature range 50°C to 480°C (120°F to 899°F), Digital display shows °F or °C, Maintains idle temperature within 1.8°F (1°C) when set to 400°F to 899°F (200 to 480°C)

Ceramic heating element and sensor ensures rapid heat-up temperature and fast thermal recovery

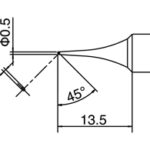

Wide selection of tips available for soldering SMD and through-hole applications, Use with Hakko T18 series tips (Standard Tip is included, others purchased separately)

Password protected temperature setting functionality

£177.91 Excl. VAT

Available for order*

DISCONTINUED – NO LONGER AVAILABLE TO PURCHASE

The FX888D-SET1 Soldering Station and T18 Soldering Tip Set set includes additional HAKKO T18 tip set of T18-BL, T18-C3, T18-D16, T18-D24, T18-S3

Introducing the HAKKO FX888D Soldering Station and T18 Soldering Tip Set – Reliable digital technology by HAKKO –

Excellent thermal recovery

- Heater output has been increased by 30% compared to that of the conventional models HAKKO 936/937. Also HAKKO FX888D delivers excellent thermal recovery by using T18 series soldering tips for their terrific heat conductivity.

This allows soldering at a lower set temperature and reducing the thermal impact on components as well as tip oxidation that can shorten tip life. - Thermal recovery graph

Rise time to 350°C is 20 seconds faster and tip temperature drop is reduced during continuous work.

- HAKKO FX888D performance comparison graph with conventional stations Able to shorten the time required for the same work and improve work efficiency significantly.

Designed to be User-Friendly

- Small footprint

Compact station body requires a space of only 100 (W) x 120 (D) mm. What’s more, points that come into contact with the floor are positioned as close to the outer edge of the body as possible to improve stability and make the station difficult to fall over. - Simple and easy operation

With only two operation buttons of UP and ENTER in the center, operation is simple and easy. Even if you’re not familiar with operation of machines, you can operate it without difficulty.

Iron holder with full of functions

An iron holder of the same color of a soldering station comes as a set. The highly functional iron holder not only improves ease of use, but also brings a sense of visual consistency to the work environment.

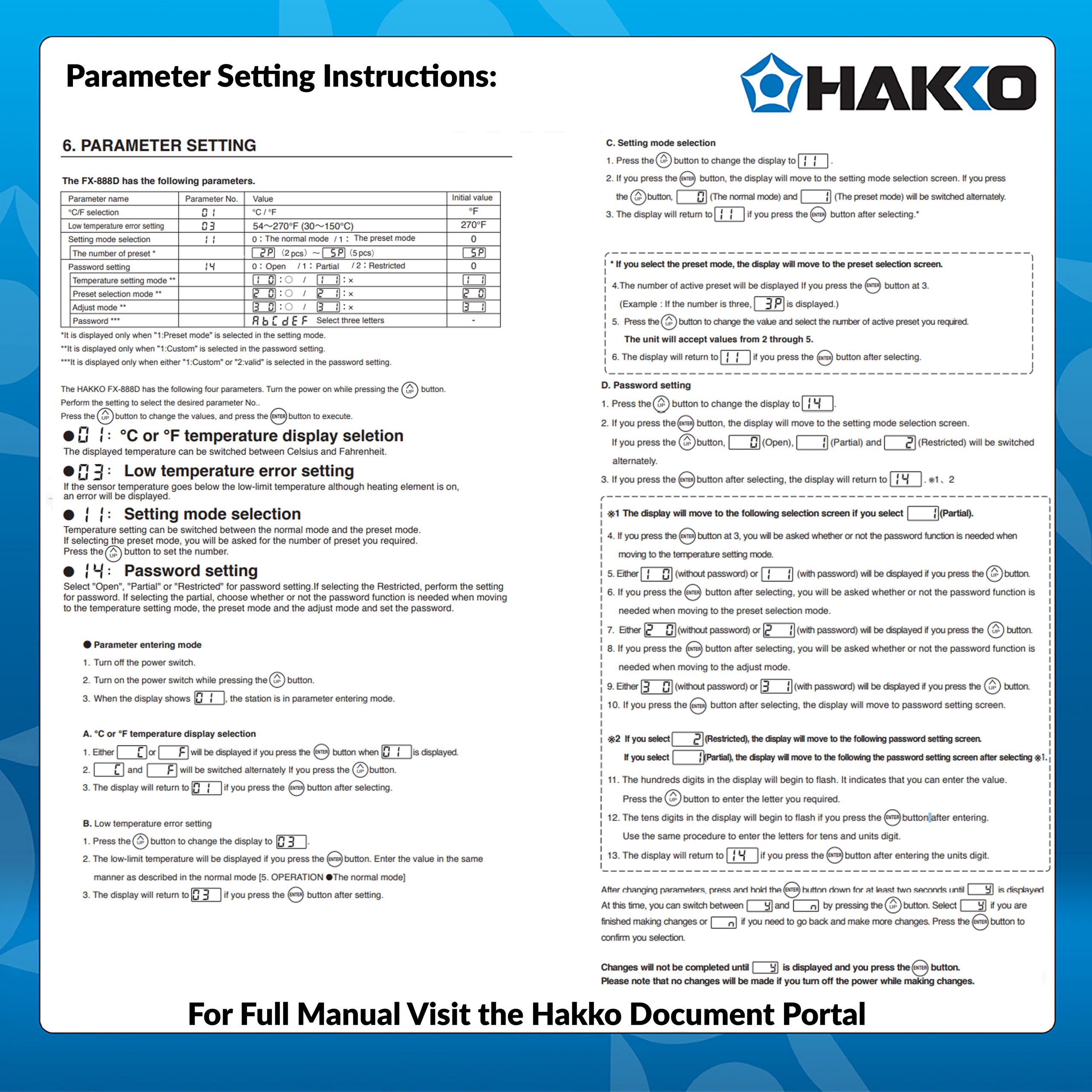

Strict temperature management

- Digital display

The HAKKO FX888D’s digital display makes it easy to check the set temperature at a glance.

- Password function

Settings can be locked using a password to prevent them from being changed unexpectedly. Of course, it is possible to restrict all setting changes or prevent users from switching to particular modes. It allows you to choose a style of usage best suited for your worksite. - Preset mode

This feature is very convenient when you want to change the set temperature to suit a particular workpiece, component, or tip shape. Simply select the desired temperature from a selection of preset temperatures registered in advance. (Up to 5 preset temperatures can be registered.) Preset mode can save your trouble and improve workability.

- Adjustment mode

Temperature adjustment* is an essential part of any strict quality control system. With adjustment mode, what used to be a troublesome procedure is now as simple as entering the measured tip temperature to HAKKO FX888D.

*Adjust the tip temperature to match the set temperature in case that there is a difference between those temperatures due to tip shape, heater replacement, or other factors.

Measuring tip temperature with a tip thermometer (HAKKO FG100)

DISCONTINUED

*Rubber cleaner sold separately.

* Total length and weight (w/o cord)

| Model No. | Unit Color | Iron Holder Color | Packing list |

| FX-888D | Soldering station (FX-888D), Soldering iron (FX-8801 with soldering tip type B), Iron holder (with cleaning wire, cleaning sponge), Instruction Manual, T18 Tip Set 1 (T18-BL, T18-C3, T18-D16, T18-D24, T18-S3) | ||

| Blue-Yellow | Blue-Yellow |

Specifications

| Model No. | FX-888D |

| Power consumption | 70W |

| Temperature range | 50 to 480ºC |

| Temperature stability | ±1ºC at idle temperature (When set to 200 to 480ºC) |

Station

| Output voltage | AC 26V |

| Dimensions | 100(W)×120(H)×120(D)mm |

| Weight | 1.2kg |

Soldering Iron

| Power consumption | 65W (26V) |

| Tip to ground resistance | <2Ω |

| Tip to ground potential | <2mV |

| Heating element | Ceramic heater |

| Standard tip | Shape-B (No.T18-B) |

| Cord length | 1.2m |

| Total length | 217mm (with B tip) |

| Weight | 46g (with B tip) |

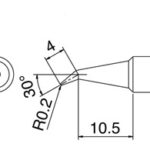

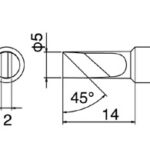

T18 Series

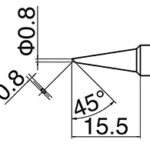

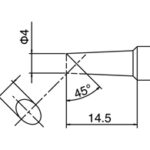

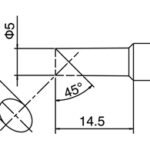

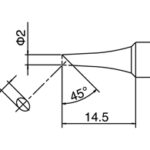

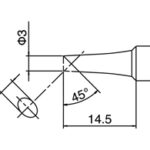

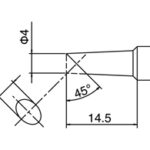

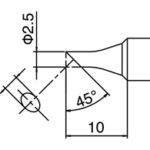

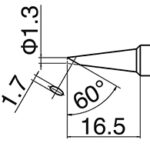

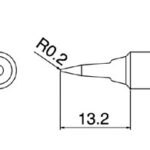

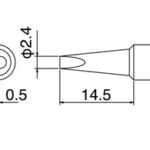

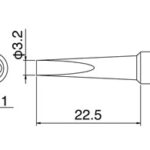

Shape BC/C

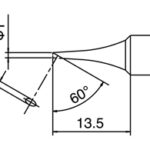

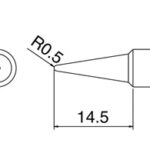

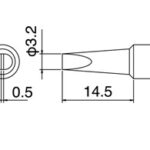

Shape B

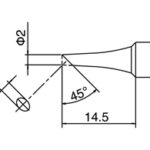

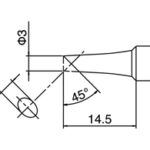

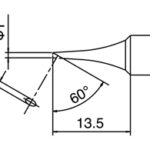

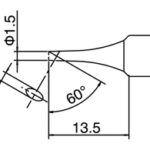

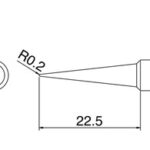

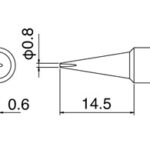

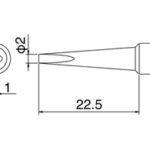

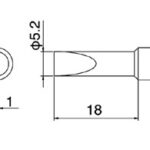

Shape D

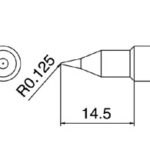

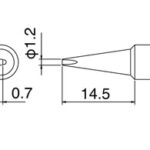

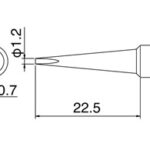

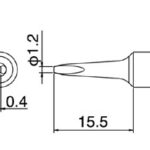

Shape I

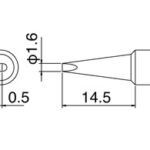

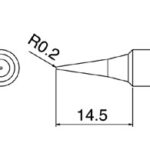

Shape J

Shape K

Optional / Recommended Extras

| Images | Part Number | Description | Availability |

| T18 Series Tips | Come in a variety of shapes and sizes for different applications | ||

| FX8802-01 | Nitrogen Soldering Iron* Requires Nitrogen Source | Buy Now |

| FX8803-02 | One Handed Soldering Iron with Solder Feed | Buy Now |

| FX8804-02 | SMD Hot Tweezers | Buy Now |

| FX8805-01 | Heavy Duty Soldering Iron with T19 Tip | Buy Now |

| B3474 | Rubber Tip Cleaner | Buy Now |

| C1437 | Iron Stand for FX8803 | Buy Now |

| FH800-04 | Iron Stand for FX Soldering Irons | Buy Now |

| 599B | Soldering Tip Cleaner | Buy Now |

| FG-100B | Tip Thermometer | Buy Now |

| 611 | 611 Solder Wire Holder | Buy Now |

| FT700 | Soldering Iron Cleaner + Polisher | Buy Now |

| FA-400 | Desk Top Fume Extractor | Buy Now |

| B2300 | Heat Resistant Pad | Buy Now |

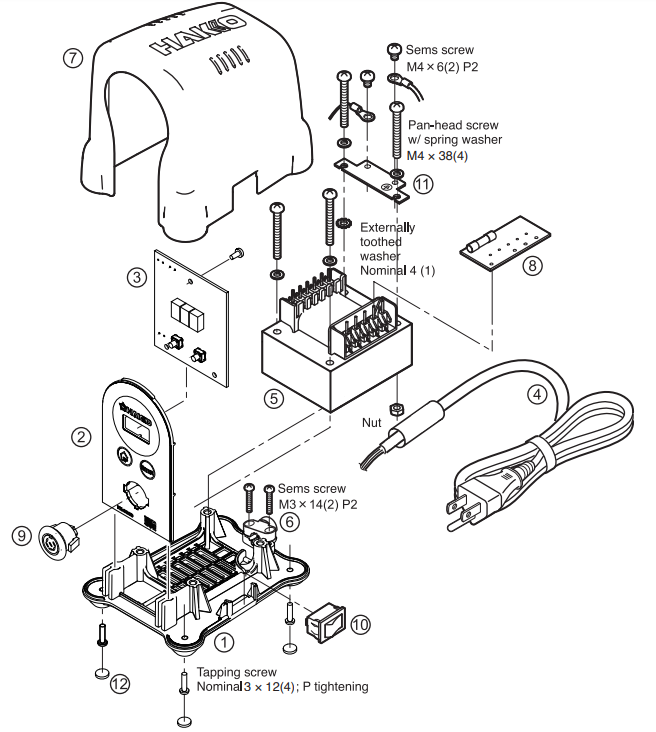

FX-888D Station Replacement Parts

| Ref. | Image | Part Number | Description | Availability |

| 1. |  | B3733 | Chassis | Buy Now |

| 2. |   | B3734 B3735 | Front Panel / Yellow Front Panel / Silver | Buy Now Buy Now |

| 3. |  | B3736 | P.W.B Temperature Control | Buy Now |

| 4. |  | B3745 | Power Cord (BS) | Buy Now |

| 5. |  | B3739 | Transformer 220-240V | Buy Now |

| 6. |  | B3750 | Cord Stopper | Buy Now |

| 7. |   | B3450 B3452 | Upper Case Blue Upper Case Silver | Buy Now Buy Now |

| 8. |  | B3723 | P.W.B / 230V | Buy Now |

| 9. |  | B3463 | Receptacle | Buy Now |

| 10. |  | B2852 | Switch | Buy Now |

| 11. |  | B2227 | Grounding Plate | Buy Now |

| 12. |  | B2405 | Rubber Feet | Buy Now |

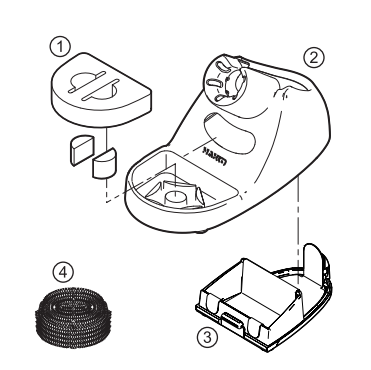

FH800 Iron Holder Replacement Parts

| Part Number | Description | |||

| FH800-BY FH800-SV | Iron Holder Blue Iron Holder Silver | Buy Now Buy Now | |

| 1. |  | A1559 | Cleaning Sponge | Buy Now |

| 2. |   | B3472 B3473 | Iron Holder Base Blue Iron Holder Base Silver | Buy Now Buy Now |

| 3. |  | B3751 | Bottom Plate with Rubber Sheet & Feet | Buy Now |

| 4. |  | A1561 | Cleaning Wire | Buy Now |

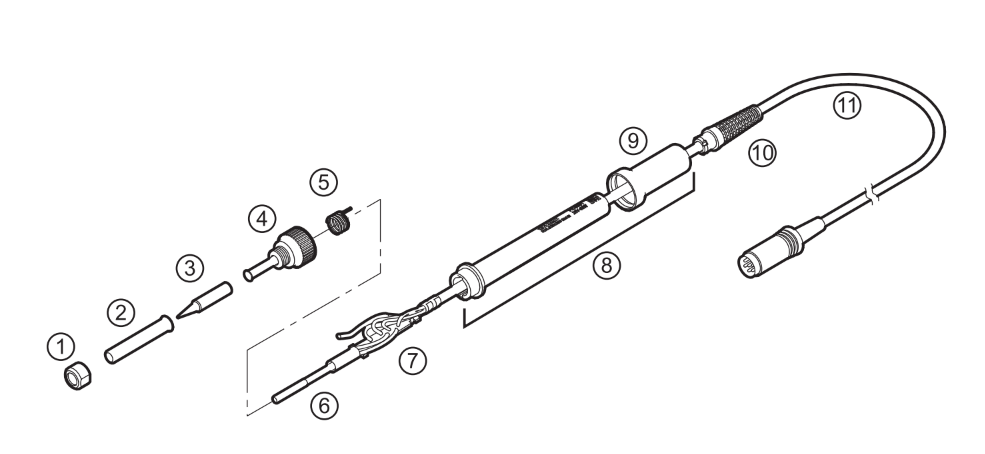

FX8801 Soldering Iron Replacement Parts

| Part Number | Description | |||

| 1. |  | B1785 | Locking Nut | Buy Now |

| 2. |  | B3469 | Tip Enclosure | Buy Now |

| 3. | Tip | T19 Series Tip | See Tips Tab | |

| 4. |  | B2022 | Nipple | Buy Now |

| 5. |  | B2032 | Grounding Spring | Buy Now |

| 6. |  | A1560 | Heating Element 26V-65W | Buy Now |

| 7. |  | B2028 | Power Cord | Buy Now |

| 8. |  | B3470 | Handle | Buy Now |

| 9. |  | B3471 | Handle Cover | Buy Now |

| 10. |  | B3467 | Cord Brushing | Buy Now |

| 11. |  | B3468 | Cord Assembly | Buy Now |

Tech Tips

| Category | Title |

|---|---|

| How to use | Select Tip Shape |

| How to use | Difference between BC/C type and BCF/CF type |

| How to use | HAKKO N2 system |

| Maintenance | Why doesn't solder flow evenly onto a tip though it is brand-new? |

| Maintenance | If solder does not flow onto the tip... |

| Maintenance | Tip life |

| Maintenance | Why do tips oxidize easily when they are used with lead-free solder? |

| Maintenance | Maintenance and inspection of station-type soldering irons |

| Top Tips | Top Tips for Successful Soldering and De-Soldering Processes |

Videos

| Preview | Title |

|---|---|

| changing the display between ℃ and ? |

| how to set "Password Lock" |

| how to set "Preset Mode" |

| how to use "Adjust Mode" |

| how to use "Parameter Settings" |

| Weight | 2.135 kg |

|---|

You may also like…

- Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering iron stands / holders, Desoldering equipment, Desoldering Tools, Hot tweezers for stations, SMD rework, Rework tools, Hot tweezers, Spare parts, Replacements for units, FR-701, Replacements for rework stations, FX-889

FX8804 Hot SMD Tweezers

Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering iron stands / holders, Desoldering equipment, Desoldering Tools, Hot tweezers for stations, SMD rework, Rework tools, Hot tweezers, Spare parts, Replacements for units, FR-701, Replacements for rework stations, FX-889

Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering iron stands / holders, Desoldering equipment, Desoldering Tools, Hot tweezers for stations, SMD rework, Rework tools, Hot tweezers, Spare parts, Replacements for units, FR-701, Replacements for rework stations, FX-889FX8804 Hot SMD Tweezers

Hot tweezers designed exclusively for HAKKO FX-888D, FX-889, FR-701 and FR-702

FX-8804 enables the easy removal of SMD chips and flat packages of up to 25mm

The iron holder clip allows accurate positioning of the tipSKU: HFX8804-02 - Shop by brand, HAKKO, Soldering equipment, Soldering stations, SMD rework, Rework stations, Desoldering / rework stations

FX-889 Duel Port Soldering Station

Shop by brand, HAKKO, Soldering equipment, Soldering stations, SMD rework, Rework stations, Desoldering / rework stations

Shop by brand, HAKKO, Soldering equipment, Soldering stations, SMD rework, Rework stations, Desoldering / rework stationsFX-889 Duel Port Soldering Station

Dual port station allows 2 handpieces to work simultaneously

Digital Station at Analog Pricing

Many functions – Adjust mode, Preset Mode, Passoword function

N2 iron (FX-8802) as an optional accessarySKU: HFX889-16 - Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering stations

DISCONTINUED FX-888D Digital Soldering Station Blue/yellow – DISCONTINUED

Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering stations

Shop by brand, HAKKO, Product catalogue, Soldering equipment, Soldering stationsDISCONTINUED FX-888D Digital Soldering Station Blue/yellow – DISCONTINUED

DISCONTINUED – Superseded by FX888DX-44BY

- Digital model in an analog-model price bracket

- Features adjustment mode, preset mode, and password function

- Separable tip/heater design provides excellent value for money

- Selectable soldering iron for N2 system as usage at your option

SKU: HFX888D-17BY