No products in the basket.

Product catalogue, Soldering iron tips, T50 Series

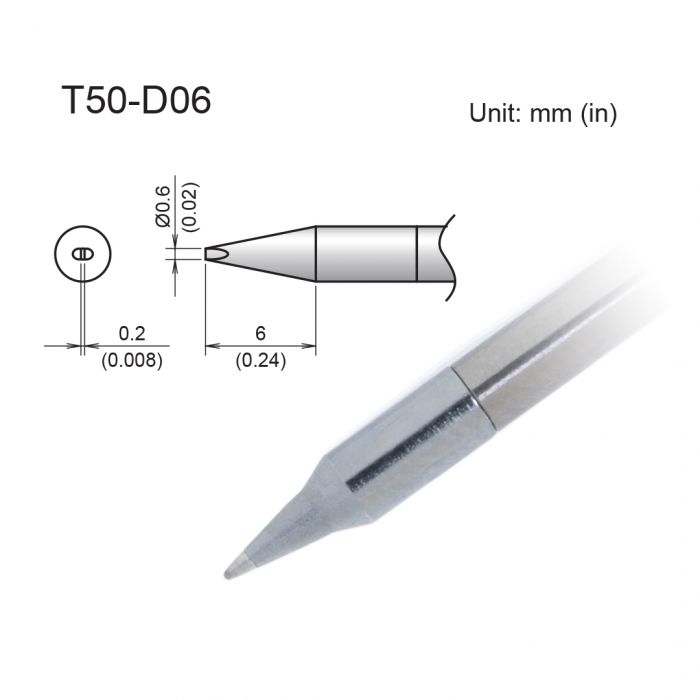

T50-D06 Micro Soldering Iron Tip – Chisel

SKU: HT50-D06

Availability:

In stock

Hakko micro soldering iron tip used with the FX9703 micro soldering iron used with the FX971 and FX972 Soldering Stations

T50 Composite Tip design includes the sensor within the tip allowing for faster more accurate thermal adjustments and greater stability.

£36.57 Excl. VAT

In stock

How to use Shape D and examples

This shape is capable of any soldering by placing the tip end in 2 ways: line and face. Therefore it requires soldering skill such as Shape B.

| Line example Shape D is also available for soldering at narrow pitches by placing the tip end in Line. Shape D is also available for soldering at narrow pitches by placing the tip end in Line.T12 series has ten kinds of Shape D which has the variation of Line width from 0.5mm to 1.2mm. |

Soldering tiny chip parts such as 0603

| Put the tip end to the land. * Soldering tip in the picture is T30-D06 with an N2 system iron for pre-heating effect. Some IC is specified by manufacturer not to be touched electrode by tip end.

The other tip shapes are recommended. |

Soldering chip parts

| Put the tip end to the land and drag the tip slowly while feeding solder. Some IC is specified by manufacturer not to be touched electrode by tip end. The other tip shapes are recommended. |

Drag soldering

| Put the tip end to the leads and drag it slowly. Apply flux to leads and land pads before soldering. It prevents the troubles such as solder bridge.

Check the right timing to feed solder. The other tip shapes are recommended. |

Pre-tinning lead wire

| Put the cut surface to the lead and drag the tip slowly while feeding solder. |

Point soldering

| PTH

| ||||

| QFP Put the tip end to the leads and drag it slowly. The other tip shapes are recommended. |

Soldering cup terminals

|

Get rid of gold plating of terminal and pre-tin lead wire. It makes solder spread over the terminal |

Melting and removing coil coatings

|

The other tip shapes are recommended. |